Rocscience | Geotechnical Software for Open Pit Mining Featured

Surface mining, whether you call it open pit, opencast, or open cut is a common method of extracting minerals like coal, iron, gold, and copper from shallow depths below the ground. Slope stability analysis for mining projects has evolved over the years, from basic kinematic and 2D limit equilibrium analysis to 3D limit equilibrium and 2D and 3D finite element and distinct element analysis.

What are some of the open pit mining challenges that geotechnical engineers are facing?

Primarily stability, often measured in terms of design acceptance criteria, must be ensured at all stages of a mining project from concept study to mining operations and mine closure. There are numerous factors that must be considered in stability analysis. These include:

Safety

Slope stability will always be the most critical factor for mining projects. Instability from inadequate understanding of ground conditions can lead to unexpected events resulting in injury, delays to production and damage to critical infrastructure.

Time constraints

New geology, structure or water information can require slope designs to require reassessment. Having the right design tools to allow efficient and detailed analysis will assist with the time constraints often thrust upon geotechnical engineers. Further, changes in commodity prices can also lead to hasty changes in the mine design, which then require new geotechnical assessment in short time frames.

Limited data

Working with limited material strength and structure data can lead to high levels of uncertainty in design. In these scenarios, geotechnical engineers need to consider natural variation and account for unknown values using statistical analysis.

Create a safer open pit mine environment with analysis

In a high-risk industry like mining, slope stability analysis is crucial at every step – from planning to excavation and mine closure.

Common practices that geotechnical engineers are using to improve their designs are –

- Verifying results with multiple numerical programs (LEM & FEM, or 2D & 3D)

- Searching for multiple critical failure regions across their whole models

- Using probabilistic analysis to account for statistical variation and unknown values

- Calibrating models with monitoring data

Rocscience Software suitable for Open Pit Mining

With the right tools by your side, you can increase ore extraction, and ensure the stability of the mine and the safety of the workers, while reducing time spent on analysis.

Slide2

2D Limit Equilibrium Analysis

With the comprehensive capabilities of Slide2, ensure the stability of your pit slopes by identifying multiple critical failure regions across your model using Multi Modal Optimization. Run probabilistic analysis to account for statistical variance in your data and leverage the integration with Slide3 to compare and validate your results between 2D and 3D analyses or with RS2 to compare LEM and FEM results. Test the sensitivity of slope stability with varying groundwater conditions using static, steady state or transient groundwater conditions.

Slide3

3D Limit Equilibrium Analysis

Slide3’s 3D capabilities assist geotechnical engineers to assess pit-wide stability in one model. Constructing slope stability models is easier and faster than ever before. Import surfaces from geological modelling or mine planning software or use built-in surface construction methods using coordinates or borehole data. Choose to build surfaces from point cloud data or import block models from applications such as Leapfrog, Deswik, Datamine, and Vulcan. Search for multiple critical failure surfaces with the advanced Multi-Modal Optimization algorithm and leverage the integrations with Slide2, RS3, and RSData, further compare & verify the results of your analyses.

RS2

2D Finite Element Analysis

RS2’s powerful continuum modelling capabilities can help you effectively analyze stress conditions, deformation and determine required support forces at static, steady state, or transient groundwater conditions. The Strength Reduction Method can further be used to validate 2D LE results from Slide2 after simply dropping and dragging models into RS2, giving you more confidence in the slope design process. Perform dynamic analysis and assess the stability of jointed rock slopes using explicit joints, joint networks, or ubiquitous joint analysis.

RS3

3D Finite Element Analysis

Analyze stresses and deformation in true 3D space. Locate the critical failure zones and calculate the Strength Reduction Factor to verify 3D LE results. Utilize the extensive material model library, dynamic analysis, and built-in groundwater seepage module for the most in-depth 3D analysis. The interoperability with other programs like RS2, Slide3, and RSData allows you to quickly import 2D and 3D models and verifying slope stability results.

SWedge

Surface Wedge Analysis for Slopes

Assess the stability of up to five-face wedges under various loads with SWedge, importing defect data directly from Dips. Calculate the Factor of Safety and Probability of Failure of wedge stability at varying groundwater conditions and determine required support to meet design acceptance criteria using the extensive built-in support library.

RocFall2

2D Analysis of Slopes at Risk of Rockfalls

Efficiently calculate rockfall runout using either Lumped Mass of Rigid Body analysis using built-in libraries of rock shapes or imported geometries from your survey. Calculate velocity, bounce height and runout to determine suitable remedial controls such as mechanical barriers or waste rock berm requirements. Integrate RocFall2 with RocFall3 to unlock additional capabilities of importing and exporting models and comparing and verifying results.

RocFall3

3D Analysis of Slopes at Risk of Rockfalls

Comprehensively analyze rock fall potential and runout with RocFall3. Like RocFall2 you can run Lumped Mass or Rigid Body analysis and assess barrier requirements using extensive in-built libraries of commercial barriers. Create 3D models by extruding RocFall2 models, import DEM’s or create your own surface using RocFall3’s Terrain Generator application. Quickly compare 3D results with 2D results using the 2D section creator.

Dips

Graphical and Statistical Analysis of Orientation Data

Analyze almost any type of orientation based geotechnical data and successfully determine the possibility of structural failure in your mining project. Save time extracting and importing any form of columnized Excel Data into Dips using its versatile Import Wizard. Taking advantage of the integration with SWedge and UnWedge, send set statistics directly from Dips to these programs for faster Probabilistic and Deterministic Analyses.

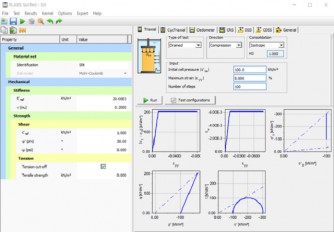

RSData

Strength & Stress Analysis of Rock and Soil Materials

Seamlessly analyze & calibrate your material models for your open-pit mining projects with RSData’s strength & stress-strain analysis capabilities. Combining lab data and multiple rock samples, rapidly calculate rock mass strength and compare the results side by side in no time. With integrations with Slide2, Slide3, RS2 & RS3, you can incorporate your materials into your models efficiently.

RocPlane

Planar Wedge Analysis for Slopes

Determine the stability of planar sliding wedges in your rock slopes. Estimate the support capacity required for design acceptance criteria. Automate the computation of numerous wedges using Automate from Excel feature in RocPlane and design adequate bench widths and slope face cuts using bench design tools to reduce the risk of slope failure. Import set and distribution data directly from Dips.

RocTopple

Toppling Stability Analysis for Slopes

Analyze 2D block or block-flexural toppling stability for your slopes at varying slope geometry and toppling block dimensions. Calculate which blocks are susceptible to toppling and sliding failure modes at varying water levels within the slope. Calculate support requirements to meet design acceptance criteria. Export results to RS2 for comparison and validation.

RSLog

Web-based Borehole Log Management

Easily manage your borehole log data. Using a web-based platform, you can access your borehole log data from anywhere on different devices. View borehole data on plan view maps linked to Google maps and create user-defined cross-sections from borehole data. Effortlessly customize the data in your reports and match your company branding with the template designer. The unique integration between RSLog and Settle3 lets you import borehole data directly into Settle3 for defining your soil layers and material properties, eliminating the need for manual data entry.

Enhance your open pit design process with Rocscience

Rocscience suite of software is packed with extensive features developed to help you with your specific open-pit mining projects.

Download the Open pit mining product sheet to learn more about the features and functionalities of our mining tools.

Want to read more like this story?

RS2

Nov, 28, 2014 | Software

3D Slope Stability Analysis of an Open Pit Mine in Minas Gerais, Brazil

Jul, 08, 2022 | NewsBy Thiago Bretas and Felipe Vilela, BVP Engenharia. Two-dimensional (2D) limit equilibrium analysis...

RocSlope

Jul, 11, 2023 | Software

PLAXIS LE

Oct, 21, 2013 | Software

How Geotech’s can overcome time crunch: UAV Photogrammetry and 3D LEM Analysis

Aug, 23, 2022 | NewsWhen it comes to open pit mines, generally, the steeper the slopes, the greater the ore extraction,...

2D or 3D LE? That is the Question - Yeager Airport Case Study

Jun, 02, 2021 | NewsWhen is 2D slope stability analysis sufficient and when should 3D analysis be used in conjunction w...

RS3

Oct, 02, 2020 | Software

Rocscience Online Course: 2D & 3D Slope Stability Analysis (October 26-27)

Aug, 24, 2021 | EventJoin Rocscience in October 2021 for an online course on 2D & 3D Slope Stability Analysis. The...

Rocscience | Vallcebre Landslide Stability Analysis Using Geophysical Data and Limit Equilibrium Methods in Slide3 and Slide2

Apr, 12, 2023 | NewsLandslides are complex bodies that are often made of heterogeneous geological materials and gradati...

Form

Looking for more information? Fill in the form and we will contact Rocscience Inc. for you.

On This Day

April 19th 1995

READ MORE

Trending

How to Determine the Basic Soil Parameters

Target at West Virginia partially collapsed due to landslide

Mine waste dam failure in Myanmar caught on video

GEO5 2022 - New Edition released!

GeoStabilization International® Earns ENR Best of the Best Award