Stabilization / Solidification (S/S)

Contents [show]

- Overview

- Theoretical Background, Advantages and Disadvantages for different S/S methods

- Field Setup

- Technology Selection

- Important Considerations

- Treatment Costs

- Quality Assurance/Quality Control (QA/QC)

- Case Studies

- Case Study #1: In-Situ treatment at South 8th Street Landfill Superfund Site, West Memphis, AR

- Case Study #2: Solidification of liquid waste contaminated with antimony, New Orleans, Louisiana (Conner, 1990; Conner, 2004), 1976

- Case Study #3: Radioactive Waste Stabilization at the US Department of Energy Savannah River Site (SRS), SC

- Recommended Reading

- References

Overview

Stabilization and solidification (S/S) is a soil remediation process by which contaminants are rendered immobile through reactions with additives or processes. During this process, also called immobilization, fixation, or encapsulation, contaminants may be chemically bound or encapsulated into a matrix. The EPA describes stabilization and solidification as a process that accomplishes one or more of the following:

- Improve handling and physical characteristics of waste;

- decrease surface area of a waste’s mass through which transfer/contaminant leakage can occur; and

- limit solubility of hazardous constituents in the waste (EPA, 1989).

Stabilization is the general term for a process that transforms contaminants into a less mobile or toxic form, while solidification is a more specific process that treats material to increase its solidity and structural integrity. Solidification does not remove nor degrade contaminants, but prevents their transport by eliminating or significantly hindering their mobility.

This process may be performed either ex-situ or in-situ. Ex-situ solidification involves excavation and backfilling, while the in-situ process requires injection of stabilizing compounds into the soil. Typical solidification agents include Type 1 Portland cement, pozzolans, lime, fly ash, and organic binders such as asphalt. A block of solidified soil is often referred to as a "monolith", or a "monofill" if the block encompasses the entire site (EPA, 1989). Stabilization/solidification is best suited for soils contaminated with metals, radionuclides, other inorganic compounds, and non- or semi- volatile organic compounds. Volatile contaminants are typically not good candidates for solidification, as the contaminants may evaporate into the atmosphere during the mixing process.

Stabilization/Solidification can be classified into three types of processes:

- Aqueous stabilization/solidification;

- Polymer stabilization/solidification, and

- Vitrification (high temperature S/S).

Figure 1: Typical S/S process: the binding agents and wasted soil are mixed with an auger (USEPA, 2012)

USEPA has identified S/S as the Best Demonstrated Available Technology (BDAT) for 57 types of hazardous wastes listed in RCRA. (Means, 1995)

About 25% of the Superfund remediation sites were treated by S/S technologies (USEPA, 2001).

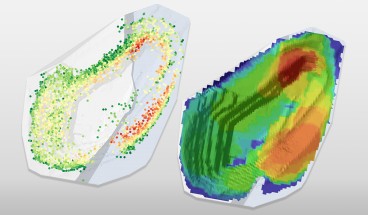

Figure 2: Frequency of application of S/S treatment compared to other technologies at U.S. Superfund sites (USEPA, 2001)

Applicability of Stabilization/Solidification Processes

Stabilization/Solidification treatment methods are applicable to a wide range of media including soils, sludges, and sediments (Wilk). Stabilization/Solidification is best suited for soils contaminated with metals, radionuclides, other inorganic compounds, and non- or semi- volatile organic compounds. The S/S process is typically able to encapsulate these contaminants in a matrix and impede their mobility. S/S methods are generally most effective on nonvolatile heavy metals (EPA, 1993). Volatile contaminants, however, are typically not good candidates for solidification. These contaminants may evaporate into the atmosphere during the mixing process and are difficult to trap within a solidification matrix. The EPA does not currently recognize stabilization as an acceptable treatment method to treat wastes contaminated with polychlorinated biphenyls.

In order to determine effectiveness of solidification for non- or semi- volatile organics, Superfund policy requires a treatability study on similar waste to ensure that the process would decrease the contaminant concentration by 90-99% (EPA, 1993). For certain constituents, the S/S process performs well at certain concentrations but poorly at others. For example, solidification of copper, lead, and zinc using cementitious materials is effective at low to moderate concentrations. However, these metals interfere with the immobilization process at higher concentrations and render it less effective (EPA, 1993). The specific mix and distribution of contaminants in the soil also affects the effectiveness of the S/S process. Table 1 below summarizes the effectiveness of the S/S procedure on various contaminants in soils and sludges.

Table 1: Effectiveness of Stabilization/Solidification on various contaminants (adapted from EPA’s "S&S of Organics and Inorganics", 1993)

| Contaminant Group | |||

| Organics | Inorganics | Reactive Compounds | |

| Demontrated: Successful tests performed | Halogenated semivolatiles Nonhalogenated semi- and non- volatiles | Volatile metals Nonvolatile metals Radioactive materials Inorganic corrosives Inorganic cyanides | Oxidizers Reducers |

| Potential: Expert opinion that technology will be effective | PCBs Pesticides Dioxins/Furans Organic cyanides Organic corrosives | ||

| Ineffective: Expert opinioin that technology will/does not work | Halogenated Volatiles Nonhalogenated Volatiles | ||

Advantages and Disadvantages of Stabilization / Solidification

Sharma (2004) summarized the advantages and disadvantages of S/S technology.

S/S technology has the following advantages:

- Low cost because the reagents are widely available and inexpensive

- Can be used on a large variety of contaminants

- Can be applied to different types of soils

- Equipment is widely available and simple

- High throughput rates

However, it still has the following disadvantages:

- Contaminants are still in the soil, not destroyed or removed

- Volume of the treated wastes usually increases significantly

- Volatile organic compounds and some particulates may come out during treatment process

- Delivering reagents deep into the wastes and mixing them evenly is difficult

- In situ S/S site may not be redeveloped

- Long-term efficiency of S/S is still uncertain

Theoretical Background, Advantages and Disadvantages for different S/S methods

Stabilization/Solidification methods have been classified into various categories by different researchers, including US EPA, Jesse Conner, and H.D. Sharma, using differing classification methods.

According to US EPA (1986), most stabilization/solidification systems are proprietary processes involving the addition of absorbents and solidifying agents to a waste. However, the S/S processes can generally be divided into five categories based on the additives used: (1) Sorption, (2) Lime-fly ash pozzolan process, (3)Pozzolan-portland cement systems, (4) Thermoplastic microencapsulation, and (5) Macroencapsulation.

Conner (1998) categorized these processes into three major categories by the mechanism of the involved processes: (1) chemical processes, such as cement-based process, pozzolan-based processes, lime-based processes, etc; (2) physical processes, such as macroencapsulation/containerization and non-chemical microencapsulation; and (3) thermal processes, such as thermoplastic polymer encapsulation and vitrification.

Sharma (1994) divided the S/S methods into two categories by the treatment materials: (1) sorbents involving sorption, and (2) encapsulating agents, involving macro-encapsulation and micro-encapsulation.

Below, we consider the types of S/S based on the classification of USEPA (1986). For each type of S/S method, applicability, advantages, disadvantages and other concerns are discussed.

Sorption

General background

Sorption is often used to eliminate free water and improve handling of wastes, such as limiting the escape of volatile organic liquids. Sorbents are also used to modify the chemical environment to limit the solubility of the waste. (USEPA, 1986)

The wastes considered for S/S treatment are mainly liquids or sludges (USEPA, 1986). In order to prevent the liquid from draining from the wastes, and to improve the handling properties of the waste, sorbents are added to the wastes. This process is referred to as sorption. Sorption may be realized through a chemical reaction between wastes and sorbents or by sorbent molecules retaining moisture as part of the capillary liquid (USEPA, 1986). Some typically used sorbents are activated carbon, anhydrous sodium silicate, various forms of gypsum, celite, clays, expanded mica, and zeolites (Sharma, 1994).Sorption can be divided into two different processes based on physical mechanisms: absorption and adsorption. Absorption involves "the uptake of a substance into the bulk of the sorbent. This process occurs via the pore structure", while "adsorption refers to the surface phenomenon whereby the liquid or gaseous molecules are attracted to and retained on the sorbent surface. This process occurs either by physical forces or by chemical bonding." (Sharma, 1994; Sell, 1988) Figure 2.1 shows some different mechanisms by which sorbents retain water and ionic materials.

Technical considerations that are important in the selection of a sorbent include the quantity needed to soak up all of the liquid, compatibility of the waste and the sorbent, level and character of contamination likely introduced in the sorbent, and chemical binding properties of sorbent for certain contaminants. (USEPA, 1986) These considerations have been studied by several researchers, and the results are summarized in Table 2.1. However, the quantity of absorbent necessary to soak up all of the liquid varies widely, which needs to be determined through bench scale tests instead of simply accepting the ratios in Table 2.1.

According to USEPA (1986), most large, hazardous waste landfills are using sorption to satisfy requirements regulating burial of liquid wastes. USEPA (1986) cited a case where large-scale sorption was successfully applied; in this case, 5 million gallons of oil sludge from a refinery site were treated with 40,939 tons of kiln dust before placement in a landfill at a cost of approximately $15 per cubic meter.

| (a) Chemically bound water | (b) Structural water |

| (c) Surface absorbed water | (d) Capillary water or pore water |

Figure 3: Mechanisms retaining water and ionic materials on and in solid phases (USEPA, 1986)

Table 2: Natural Sorbents and Their Capacity for Removal of Specific Contaminants from Liquid Phases of Neutral, Basic, and Acidic Wastes.

| Contaminant | Neutral Waste (Calcium Fluoride) | Basic Waste (Metal-Finishing Sludge) | Acidic Waste (Petroleum Sludge) |

| Ca | Zeolite (5054)a Kaolinite (857) | Illite (1280) Zeolite (1240) Kaolinite (733) | Zeolite (1390) Illite (721) Kaolinite (10.5) |

| Cu | Zeolite (8.2) Kaolinite (6.7) Acidic fly ash (2.1) | Zeolite (85) Kaolinite (24) Acidic fly ash (13) | Zeolite (5.2) Acidic fly ash (2.4) Kaolinite (0) |

| Mg | Basic fly ash (155) | Zeolite (1328) Illite (1122) Basic fly ash (176) | Zeolite (746) Illite (110) Basic fly ash (1.7) |

| Zn | Zeolite (10.8) Vermiculite (4.5) Basic fly ash (1.7) | ||

| Ni | Zeolite (13.5) Illite (5.1) Acidic fly ash (3.8) | ||

| F | Illite (175) Kaolinite (132) Acidic fly ash (102) | Kaolinite (2.6) Illite (2.2) | Illite (9.3) Acidic fly ash (8.7) Kaolinite (3.5) |

| Total CN | Illite (12.1) Vermiculite (7.6) Acidic fly ash (2.7) | ||

| COD | Acidic fly ash (690) Illite (108) | Illite (1744) Acidic fly ash (1080) Vermiculite (244) | Vermiculite (6654) Illite (4807) Acidic fly ash (3818) |

a Values in parentheses represent sorbent capacity in micrograms of contaminant removed per gram of sorbent used.

Disadvantages of Sorption

In many cases waste constituents may leach from the sorbents, which is an important source of pollution. Thus, sorbents are often used in lined landfills to control the pressure head on the liner, while the leaching is protected mainly by the liner. (USEPA, 1986)

Cementitious Stabilization/Solidification

General background

USEPA (1997) defines cementitious S/S technologies as those that use "inorganic reagents to react with certain waste components; they also react among themselves to form chemically and mechanically stable solids." This is a conventional method used for S/S. Common reagents include Portland cements, fly ash, and lime and kiln dust. These reagents usually react to form a solid matrix, which is often stable and has a rigid, friable structure like many soils and rocks (USEPA, 1997). Cementitious S/S reagents are often called "inorganic polymers". Typically, the S/S process is realized through hydration of Portland cement. In the presence of water, C3S and C2S in cement hydrate to form calcium silicate hydrate gel (C-S-H gel) and Ca(OH)2. C3A hydrates to form calcium trisulfoaluminate hydrate, or calcium monosulfoaluminate hydrate, or tetracalcium aluminate hydrate (Spence and Shi, 2004). These products form hardened paste, mentioned as a solid matrix previously.

Advantages of Cementitious Stabilization/Solidification

Advantages of cementitious S/S include the wide availability of cementitious reagents, which are inexpensive and can be operated simply. Among them, Portland cement is the most commonly used (Spence and Shi, 2004).

Disadvantages of Cementitious Stabilization/Solidification

The final pH of the system may not be desirable. There is an optimum pH range to precipitate amphoteric metals is about 10, such as Cd, Cr, Cu, Pb, Ni, and Zn. However, the pH value of a hardened Portland cement is over 12.5. (Spence and Shi, 2004)

Many contaminants interfere with the hydration of Portland cement. (Spence and Shi, 2004)

Portland cement cannot control the oxidation state of metals. (Spence and Shi, 2004)

As recommended by Spence and Shi (2004), these disadvantages can be solved by adding various additives into Portland cement, which includes blast furnace slag, pozzolan and fly ash. These additives not only serve to improve the performance of Portland cement as S/S reagents, but also help to cut down the cost.

Polymer Stabilization/Solidification

General background

As defined by USEPA (1997), "polymer S/S technologies process waste at relatively low temperature by combing or surrounding wastes with liquid polymers. Cooling or curing of the polymer then produces a solidified final waste form product".

Polymer S/S is a versatile technology which can be applied for either microencapsulation or macroencapsulation; also can be accomplished ex situ or in situ (USEPA, 1997). USEPA (1997) divided polymers into two categories: thermoplastic and thermosetting. Thermoplastic binders can be melt to a flowable state when heated and harden to a solid when cooled, while thermosetting binders require the combination of several ingredients to polymerize and harden (irreversible) (USEPA, 1997).

When the waste particles are small solid particles ( 60 mm), clean polymer can be placed around the waste and this process is usually called macroencapsulation. USEPA has identified macroencapsulation as the best demonstrated available technology (BDAT). (Spence and Shi, 2004)

Advantages of Polymer Stabilization/Solidification

Polymer S/S is useful because of its broad application to diverse waste streams. Additionally, polymer S/S results in waste products with improved durability and leachability characteristics compared to cementitious techniques (Weitzman et al., 1997). Polyethylene, one of the most common polymers used for S/S, is relatively inexpensive; costs for 1kg of salt waste are estimated around $1.88, compared to 3.00 for cement (Conner and Hoffner, 1998).

Both thermoplastic polymers and organic polymers are hydrophobic after curing and thus resist leaching, even at very small particle sizes. This property makes polymers ideal for trapping highly toxic metals and organic compounds. Organic polymer microencapsulation, specifically, is a useful method to encapsulate waste because it is well-suited for many types of applications, including liquid waste solidification; it exhibits a high degree of impermeability, and can quickly attain physical strength. Organic polymer-treated wastes typically remain in solid/monolithic form because of their high strength and elasticity properties. Because organic polymers can be synthesized in a wide variety of compositions, they can be tailored to meet different requirements for wastes. This is advantageous for solidifying liquid wastes, which can have highly variable characteristics and remediation requirements (Conner and Hoffner, 1998)

Disadvantages of Polymer Stabilization/Solidification

One disadvantage of polymer S/S technologies is sensitivity to particle diameter. Microencapsulation can typically effectively treat particles between 50 µm and 3mm, while macroencapsulation is best for particles >60mm (Weitzman et al., 1997). Particles outside of these size ranges are best treated after processing or with different methods. Polymer S/S treatment also presents the problem of volatilized moisture release, especially VOCs, which can be hazardous. It is best to pre-treat wastes with more than 2% moisture (Weitzman et al., 1997).

One nearly obsolete method of organic polymer microencapsulation, Urea-Formaldehyde S/S, expels free water during the condensation reaction of stabilization. This method require large quantities of resin dispersion for solidification and is expensive for drumming radioactive wastes compared to cementitious processes. Lastly, these systems have generated concern for the environment due to the use of formaldehyde (Weitzman et al., 1997).

Organic Polymer Systems are also relatively unfashionable in recent years. In some cases, waste components may interfere with polymerization by reacting with catalysts or taking up free radicals. Polymer S/S processes often require roughly 25% by weight of polyester resin in the waste mixture, which can significantly increase costs due to chemical requirements (Weitzman et al., 1997).

Field Setup

tabilization/Solidification of contaminated soil may be performed using in-situ or ex-situ processes. In-situ stabilization involves in-place mixing of reagents and waste without removal from the contaminated site. Ex-situ processes are typically performed on-site but involve above-ground mixing; the stabilized waste is then returned to the site, placed in a landfill-type cell, or hauled away to an off-site disposal facility.

In-Situ Treatment Processes

The procedure for an in-situ treatment process may utilizes the existing lagoon as a mixing area. Large-scale remediation projects are typically better suited for in-situ remediation, which is usually less costly in such situations. From a regulatory standpoint, in-situ treatment does not trigger Land Disposal Restrictions (Andromalos et al.). Advantages of in-situ stabilization are that a smaller area is required for support and worker exposure to hazardous contaminants is minimized (Andromalos et al.). However, quality control may be difficult to achieve during in-situ mixing.

The follow steps are typical for stabilization/solidification of waste in-situ (Cullinane et al. (1986):

- Addition of reagent, such as kiln dust or flyash, using mechanical or pneumatic application.

- Mixing with backhoe or excavator until stabilization/begins.

- Setting/gelling for 24-48 hours.

- Off-gas treatment to collect hazardous vapors

See Figure 4 and Figure 5 below for a diagram of a typical in-situ stabilization/solidification treatment process.

Figure 4: Deep in-situ S/S mixing setup, including gas cap to trap vapors.

Figure 5. In-situ S/S mixing setup, with single auger. (www.wrscompass.com)

Ex-Situ Treatment Processes

Ex-Situ processes are typically performed on-site using mobile mixing equipment (NAVFAQ). Small batches of waste may also be mixed in drums. Alternatively, area mixing may be implemented, in which waste and reagent are mixed in layers at the final disposal site. Ex-situ processes provide better control over reagents, mixing, and sampling. They are more practical for shallow sites or sites without access for large machinery. Important considerations for ex-situ mixing include swelling during mixing, which can double the original volume of waste, and the generation of harmful odors, dust, and especially organic vapors that are difficult to capture.

Mobile Mixing

Mobile mixing systems utilize mobile or fixed systems to handle, meter, and mix waste and reagents. Wastes are physically removed from their location using pumping or construction equipment, mechanically mixed with reagents, and deposited into a prepared disposal site. This method is best suited for liquids and highly liquid sludges that can be pumped. Special equipment may be used to employ the mobile mixing method on high solids content sludges and soils (Cullinane, 1986). Mobile mixing plant stabilization/solidification typically requires the following project sequencing:

- Excavation to remove contaminated waste

- Classification of wastes

- Mobile plant setup and mixing

- Preparation of remedial site for installation of mobile system, including necessary utilities/electricity

- Preparation of final disposal site

- Installation of raw and treated waste handling systems, including pumps or construction equipment

- Screening of wastes to remove particles too large for treatment (typically 2 inches or greater in diameter) (EPA, 2012)

- Mixing of binding agents, water, and waste

- Off-gas treatment to collect hazardous vapors

- Final Disposal

See Figure 6 below for a typical schematic of mobile mixing processes.

Figure 6: Typical Mobile Mixing Plant Schematic. (Federal Remediation Technologies Roundtable)

In-Drum Mixing

Toxic and hazardous liquids and sludges are often disposed on-site in drums. In-drum solidification/stabilization methods aim to utilize these existing drums as both a mixing vessel and storage container for hazardous waste. When possible, reagents are added directly to the drum. However, because head space requirements include 30-50% of the drum volume, and because drum integrity degrades over time, additional drums may be required. This significantly increases treatment costs. Typical in-drum mixing processes involve the following steps:

- Evaluation/identification of contents in each drum

- Evaluation of drum condition and head space

- Preparation of materials handling location, including concrete pad or gravel surface, chemical storage, and mixing equipment

- Addition and mixing of solidification/stabilization chemicals using mixers or propellers

- Placement of drums in a secture area for curing

- Addition of inert material to any remaining head space and replacement of top to each drum

- Final disposal of drums

Area Mixing

Area mixing provides an economical method for stabilization/solidification of waste liquids and sludges without the use of conventional, stationary mixing equipment. Waste is placed in a layer over the disposal area in 2"-24" thicknesses and is then overlaid with a layer of reagents. The two layers are then lifted and turned with a mechanized vehicle, similar to tilling. The mixture is air dried or compacted and additional waste/reagent layers may be added up to the determined final material height. The final layer is typically covered with earth and seeded as a final cap. Alternatively, the waste may be removed to another disposal site, but this may leave significant areas of hazardous waste to clean up from the treatment site. Area mixing processes typically proceed as follows:

- Selection/preparation of disposal area

- Excavation and transport of waste

- Spreading of waste in desired thickness over disposal area using construction equipment

- Spreading of required amounts of reagents over waste

- Mixing of materials using high-speed rotary mixer

- Compaction of mixed layer

- Repeat steps 2-7 until allowable solidified waste height has been attained

See Figure 7 for an example of area mixing.

Figure 7: Ex situ area mixing. (unitedretekofct.com).

Technology Selection

The selection of S/S technologies is based on several factors (Wiles, 1987):

- Waste characteristics (both chemical and physical)

Waste characteristics are the most important factor in determining S/S treatment technology. See section 5 for further discussion.

- Process type and processing requirements

The types of S/S activity (in-drum, in-plant, etc.) and processing requirements (waste modification, mixing models, waste transportation/storage) should be considered during selecting a S/S technology. For example, in-drum or in-plant processes are more easily controlled than in situ process. (Wiles, 1987)

- S/S product management objective

The S/S product can be disposed in a landfill, stored, or transported elsewhere. According to regulatory requirements, the S/S products for landfill disposal and for delisting may not require the same degree of treatment. Delisting requires that the waste materials are no longer hazardous, while disposing in a RCRA hazardous waste landfill does not. (Wiles, 1987)

- Regulatory requirements

There are numerous regulations relevant to S/S processes, such as the EP, MEP, TCLP, and chemical reaction requirement for waste treatments, but these are not performance criteria which S/S products must meet. Generally, a designer will produce an S/S waste product meeting minimum requirements, i.e. removing free liquids and/or produce a solid which can be transported or stored. (Wiles, 1987)

- Economics.

The cost of different S/S methods will be discussed in following parts in detail.

Important Considerations

Compatibility of Wastes and Treatment Process

Waste characteristics are the most important concern when selecting a S/S technology. Table 3 is a summary of compatibility of different wastes with different S/S technologies provided by USEPA (1986). For example, cement-based treatment is very effective for inorganic acid wastes, because cement can neutralize acids. However, if thermoplastic microencapsulation is used to treat the inorganic acid wastes, the wastes need to be neutralized before treatment (Sharma, 1994).

Table 3: Compatibility of Selected Waste Categories with Different Stabilization/Solidification Technicues

| Waste Component | Treatment Type | |||

| Cement-Based | Pozzolan-Based | Thermoplastic Microencapsulation | Surface Encapsulation | |

| ORGANICS |

|

|

|

|

| Organic solvents and oils | May impede setting, may escape as vapor | May impede setting, may escape as vapor | Organics may vaporize on heating | Must first be absorbed on solid matrix |

| Solid organics (e.g., plastics, resins, tars) | Good-often increases durability | Good-often increases durability | Possible use as binding agent in this system | Compatible-many encapsulation materials are plastic |

| INORGANICS |

|

|

|

|

| Acid wastes | Cement will neutralize acids | Compatible, will neutralize acids | Can be neutralized before incorporation | Can be neutralized before incorporation |

| Sulfates | May retard setting and cause spalling unless special cement is used | Compatible | May dehydrate and rehydrate causing splitting | Compatible |

| Halides | Easily leached from cement, may retard setting | May retard set, most are easily leached | May dehydrate and rehydrate | Compatible |

| Heavy metals | Compatible | Compatible | Compatible | Compatible |

| Radioactive materials | Compatible | Compatible | Compatible | Compatible |

Reproduced from: USEPA, 1986

Pre-treatment Process

Numerous pre-treatment techniques can be used to render stabilization/solidification more effective. These include:

- Destruction of materials that interfere with solidification reagents, such as acids or oxidizers.

- Reduction of total volume of waste to be treated, using processes such as dewatering or settling.

- Chemical binding of certain toxic waste constituents to solid phases, removing them from solution.

- Improving the scale of waste processing, i.e. bulking and homogenizing waste so that the number of waste forms to be treated is reduced.

Compatibility problems can be addressed by pretreatment of wastes. Pretreatment methods serve to bring the chemical waste into an inert or less soluble form. This process improves the efficiency of S/S and reduces the cost.

Generally, the most widely used pretreatment methods are (Sharma, 1994):

- Neutralization

- Oxidation-reduction

- Chemical scavenging

- Other pretreatment methods, such as dewatering and consolidation, removal of volatile organics, etc.

Treatment Costs

Costs for Different Construction Methods

A summary of cost comparisons for four different S/S construction methods is given in Table 4. The actual costs may be different today because of changes in reagent costs and labor costs, but the relative costs should be the same.

- In-drum mixing is the most expensive and time-consuming, while the costs and treatment time of the other four are more consistent;

- Costs can be cut down by changing the reagents used, but this is not effective for in-drum mixing because costs of reagents occupy a small proportion of total costs.

Table 4: Summary comparison of relative costs for different S/S construction methods

| Parameter | In Drum | In Situ | Plant Mixing | Area Mixing | |

| Pumpable | Unpumpable | ||||

| Metering and mixing efficiency | Good | Fair | Excellent | Excellent | Good |

| Processing days required | 374 | 4 | 10 | 14 | 10 |

| Cost/ton |

|

|

|

|

|

| Reagent ($) | 20.50 (9%) | 20.50 (63%) | 20.50 (53%) | 20.50 (42%) | 20.50 (49%) |

| Labor and per diem ($) | 51.07 (23%) | 1.36 (4%) | 3.83 (10%) | 6.93 (14%) | 6.35 (15%) |

| Equipment rental ($) | 37.14 (17%) | 1.38 (4%) | 3.93 (10%) | 7.54 (16%) | 4.07 (10%) |

| Used drums at $11/drum ($) | 48.18 (21%) | - | - | - | - |

| Mobilization-demobilization | 15.68 (7%) | 1.58 (5%) | 1.43 (4%) | 2.26 (5%) | 1.20 (3%) |

| Cost of treatment process | 172.57 | 24.83 | 29.69 | 37.23 | 32.11 |

| Profit and overhead (30%) | 51.72 (23%) | 7.45 (23%) | 8.91 (23%) | 11.17 (23%) | 9.63 (23%) |

| Total cost/ton ($) | 224.29 | 32.28 | 38.60 | 48.40 | 41.75 |

Reproduced from: USEPA, 1986

Costs for Different S/S Processes

USEPA (1996) summarized the costs for different S/S processes from information provided by the companies owning the processes. According to the results, the relative costs for different methods are:

- Lime/ash method

Factors Affecting Treatment Costs

- Type of waste

- Moisture content in waste increases costs compared to solid waste;

- Contaminant concentration and type, which determines the amount of reagents used.

- Size of S/S site

- The larger the site, the easier the scenario and the lower the cost.

See table 5 below for a comparison of various site/treatment difficulty scenarios.

Table 5: Costs for different site size/treatment level scenarios.

| Racer parameters | Small site | Large site | ||

| Easy | Difficult | Easy | Difficult | |

| Cost per ft3 | $6 | $7 | $4 | $5 |

| Cost per m3 | $216 | $248 | $124 | $190 |

| Cost per yd3 | $165 | $189 | $94 | $144 |

Reproduced from: www.frtr.gov

Quality Assurance/Quality Control (QA/QC)

QA/QC are operations conducted to ensure that the S/S product meets requirements. Typical objectives for S/S treatment of wastes include (Shi, 2004):

- Contaminant mobility (leachate) reduction

- Support strength

- Environmental durability

- Low hydraulic conductivity

QA/QC plans are necessary to ensure these objectives can be achieved. QA/QC plans usually involve a series of pre-treatment and post-treatment tests. These include tests on the cement and additives, wastes, mixing water, freshly mixed wastes, and hardened wastes. (Shi, 2004)

- Pre-treatment testing

- Components of cement and wastes (physical and chemical characteristics)

- Mixing water (no substances, detrimental to the S/S treatment process, present)

- Bench- and pilot-scale treatment testing: a demonstration of the effectiveness of the selected treatment method.

- Post-treatment testing on freshly mixed wastes

- Content of cement or additives

- Volume increase

- Bulk density and moisture content

- Consistency

- Concentration of contaminants

- Post-treatment testing on hardened treated wastes

- Strength/penetration resistance

- Hydraulic conductivity

- Leachability

- Durability

Case Studies

This section will describe a number of different sites remediated with stabilization/solidification processes.

Case Study #1: In-Situ treatment at South 8th Street Landfill Superfund Site, West Memphis, AR

The South 8th Street Landfill was a 30-acre industrial and municipal waste landfill. Before becoming a landfill, the site was excavated for gravel, resulting in numerous borrow pits. After 1957, the pits were used for disposal of industrial and municipal wastes. Between 1960 and 1970, waste oil sludge from a nearby refinery was deposited on 2.6 acres of the landfill. EPA conducted borings between 1981-1988 and found the oil sludge soil was contaminated with PAHs, PCBs, and lead.

In-situ mixing with auger reagents was utilized to remediate the soil. The following mixing proportions were used:

- Soil 64.5 percent

- AG limestone 16.1 percent

- Portland cement 12.9 percent

- Fly ash 6.5 percent

Site remediation was completed over the course of two years between 1998 and 2000. Treatment costs were approximately $106/cyd. Sampling during a five year review of the contaminated site concluded that the site achieved remediation goals and chemical and physical performance standards.

Case Study #2: Solidification of liquid waste contaminated with antimony, New Orleans, Louisiana (Conner, 1990; Conner, 2004), 1976

Background

Although this case was conducted more than 30 years ago, it is still a representative application of cement-based S/S technology (Conner, 1990). Its chemistry, delivery system, and operation are still very proper by today's standards. The waste was generated from a chemical plant in West Virginia and transported to New Orleans. It was temporarily tanked and prepared to be ocean-dumped, but ocean-dumping was stopped when 4,000,000 gallons of waste remained to be disposed of. The waste contained high levels of dissolved organics, salts and dissolved antimony. It was solidified and waited for a series of tests to verify that it was suitable for local, sanitary landfill as a non-toxic solid. (Conner, 2004)

Treatability Studies

"The waste was a low-viscosity, semi-clear solution with very little suspended solids", according to Conner (2005). Table 6 gives the results of untreated waste analyses. The state of Louisiana would allow the disposal of this waste in a local landfill if it could be treated to become a stable, portable solid with limited antimony leachability. (Conner, 2004)

Table 6: Analysis of untreated waste - case study #2

| Contaminant | Concentration (wt%) |

| Ethylene glycol | 6.6 |

| Diethylene | 0.2 |

| Sodium terephthalate | 2.5 |

| Sodium chloride | 8.3 |

| Sodium sulfate | 0.9 |

| Ammonium chloride | 1.1 |

| Antimony | 0.0234 |

Source: Conner, 2004

The S/S process was performed using a combination of Portland cement and sodium silicate solution to quickly set and harden the liquid waste. A pretreatment process with hydrated lime was used to precipitate or remove some of the dissolved organics. Pretreatment helps in avoiding organic interference with cement setting and reducing the usage of S/S reagents. (Conner, 2004)

The operational parameters for this project are listed below in Table 7 (Conner, 2004).

Table 7 Operational Parameters for New Orleans Remediation Case Study

| Volume Treated | 4,000,000 gallons |

| Treatment Rate | 130,000 Gallons/Day average |

| Time | Spring 1976 |

| Treatment Cost | $0.167/gallon |

| Disposal Method | Sanitary landfill, daily cover material |

Source: Conner, 2004

Delivery System

The delivery system for this case is shown in Figure 8. It consists of two units: a pretreatment unit and an S/S unit. The primary difference of this system is that the treatment units are completely mobile and are largely self-contained. (Conner, 2004)

Figure 8: Schematic drawing of the treatment units in Case study #2 (Conner, 2004)

Operations and Results

The immediately treated waste was quite fluid and needed to be temporarily stored in an impoundment until it was solidified. After all the waste was treated, the final sampling was done, test results were obtained and approved by the state, and the solid was excavated and transported to the final disposal site. (Conner, 2004)

For treated waste, strength tests with a penetrometer and a vendor-developed column-leaching test were carried out. The test results are listed in Table 8.

Table 8 Comparison of Treated Waste to Raw Waste Analyses – Case Study #2

| Contaminant | Concentration in Raw Waste (mg/kg) | Concentration in Treated Waste (mg/L) |

| Ethylene glycol | 66,000 | NM |

| Diethylene glycol | 2,000 | NM |

| Sodium terephthalate | 25,000 | NM |

| Sodium chloride | 8,300 | NM |

| Sodium sulfate | 9,000 | NM |

| Ammonium chloride | 11,000 | NM |

| Antimony | 234 | 0.1 |

| Chloride | NRa | 160.0 |

| Sulfate | NR | 5.0 |

| Chemical oxygen demand | NMb | 350.0 |

| a NR: Not measured and reported separately as the anion, but present in compounds listed above. | ||

| b NM: Not measured. | ||

Source: Conner, 2004

Although the results cannot be directly compared with current Toxicity Characteristic levels (The compressive strength of the solid S/S product is as high as 4 to 5 tons/ft2 (~75 psi). (Conner, 2004). These properties of the S/S products allow them to be disposed in a local sanitary landfill. The properties allowed the products to be used as daily cover material, which is a higher end use. (Conner, 2004)

Case Study #3: Radioactive Waste Stabilization at the US Department of Energy Savannah River Site (SRS), SC

Background

The Savannah River Site (SRS) is a nuclear reservation in the state of South Carolina, US. The Saltstone facilities, opened in 1990, are part of SRS and use S/S technologies to treat low-level radioactive liquid salt wastes. The facilities consists of two components: the Saltstone Production Facility (SPF) and the Saltstone Disposal Facility (SDF) ("Fact Sheet of Saltstone Facilities", 2012). The Saltstone Facility is located in the Z-Area at the SRS and it is designed to process about 30,000 gallons of waste per day. The objective of the facility is to stabilize liquid mixed waste to make the waste suitable for disposal in a Subtitle D landfill. (Conner, 2004). See the location and facility in figures 9 and 10 below.

Figure 9: Location of SRS (http://sti.srs.gov)

(a) Saltstone Production Facility (SPF)

(b) Slatstone Disposal Facility (SDF)

Figure 10: Overview of Saltstone facilities (www.flickr.com)

Components of the waste

The waste is an aqueous solution containing about 30 wt% dissolved sodium salts with radioisotopes. The salts are the product of the neutralization reaction between sodium hydroxide and acids used in the isotope extraction processes. (Conner, 2004)

Delivery System

The current Saltstone Processing Room is a hands-on-maintenance facility, as shown in Figure 11. A schematic of the facility is shown in Figure 12.

Figure 11: Processing room for SRS Saltstone facility for Case Study #2 (Conner, 2004)

Figure 12: Schematic of the SRS Saltstone Facility for stabilizing radioactive salt waste for Case Study #2 (Conner, 2004)

Operations

The Saltstone Facility began operation to treat radioactive waste in June 1990 and about 3,500,000 gallons of radioactive hazardous liquid waste and 100,000 gallons of high-solids slurry have been processed. (Conner, 2004)

The S/S treatment of Sandstone Facility is realized by combining S/S binders, cement, slag, and fly ash with waste solution. The nominal composition of the mixture is listed in Table 9. The facility processes about 100 gallons of waste solution per minute, which requires transferring about 35 tons of cementitious reagents per hour. The mixing process is executed by a twin-shaft Readco continuous processor. The waste product is pumped over 2000 ft through a 3-inch carbon steel line and is disposed in SDF.

Table 9: Nominal composition of mixture - Case study #3

| Component | Wt% of the product |

| Waste salt solution with 29 wt% radioactive dissolved sodium salts | 46 |

| Premixed reagents |

|

| Portland cement | 6 |

| Gound granulated blast furnace slag | 24 |

| Fly ash | 24 |

Source: Conner, 2004

Recommended Reading

- Handbook for Stabilization/Solidification of Hazardous Wastes, EPA/540/2-86/1001, Office of Research and Development, USEPA, Cincinnati, OH, 1986.

- Book: "Stablization and Solidification of Hazardous, Radioactive, and Mixed Wastes", edited by Roger D. Spence and Caijun Shi, CRC Press, Boca Rato, FL, 2004.

- Book: "Waste Containment Systems, Waste Stabilization, and Landfills", Hari D. Sharma and Sangeeta P. Lewis, John Wiley & Sons, Inc, New York, 1994.

- Book: "Chemical Fixation and Solidification of Hazardous Wastes", Van Nostrand Reinhold, 1990.

References

- A citizen's Guide to Solidification and Stabilization. (2012) EPA 542-f-12-019, USEPA

- Burdick S. A. and White R. M. (2000). "Pulse Wave Well Development Demonstration" http://sti.srs.gov>

- Conner, J. R., Hoeffner, S. (2004). "Case Studies: Full-Scale Operations and Delivery Systems." Stabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes, Spence, R. D. Spence and C. Shi, eds., CRC Press, Boca Raton, FL.

- Conner, J. R. (1990) "Chemical Fixation and Solidification of hazardous wastes." Van Nostrand Reinhold, New York.

- Engineering Bulletin: Stabilization/Solidification of Organics and Inorganics,(1993).EPA/540/S-92/015, Office of Research and Development, USEPA, Cincinnati, OH

- Federal Remediation Technologies Rountable. (n.d.). Solidification/Stabilization. Retrieved 14 2013, March, from Remediation Technologies Screening Matrix and Reference Guide: http://www.frtr.gov/matrix2/section4/4-21.html

- Handbook for Stabilization/Solidification of Hazardous Wastes. (1986). EPA/540/2-86/1001, Office of Research and Development, USEPA, Cincinnati, OH

- Innovative Site Remediation Technology, Design and Application, Stabilization/Solidification. (1997). Vol. 4, EPA/542/B-97/007, Office of Solid Waste and Emergency Response, USEPA, Washington, DC

- Innovative Treatment Technologies: Annual Status Report, 10th Edition, (2001). EPA-542-R-01-004, February 2001.

- "In Situ S/S Using Soil Mixing." Geo-Solutions. www.geo-solutions.com>

- Means, J. L. et al. (1995). "The application of Solidification/Stabilization to Waste Materials". Lewis Publishers, Boca Raton, FL

- Naval Facilities Engineering Command. (n.d.). Solidification Ex Situ (Stabilization). Retrieved March 12, 2013, from NAVFAQ Engineering Service Center: https://portal.navfac.navy.mil>

- "Saltstone Facilities, Fact Sheet". (2012). Savannah River Remediation.

- Savannah River Site's photostream www.flickr.com >

- Sharma, H. D., and Lewis, S. P. (1994). "Waste Containment Systems, Waste Stabilization, and Landfills: Design and Evsuialuation." Wiley, New York

- Sharma, H. D., and Reddy, K. R. (2004). "Geoenviromental Engineering: Site Remediation, Waste Containment, and Emerging Waste Management Technologies." Wiley, New York

- "Soil Stabilization Brings New Life to Old Utility Site" Slag Cement Association. www.slagcement.org>

- "Soil mixing & Soil Stabilization." WRS Compass. www.wrscompass.com>

- Spence, R. D. and Shi, C. J. (2005). "Stabilization and Solidification of Hazardous, Radioactive, and Mixed Wastes." CRC Press, Boca Raton, FL

- Stabilization/Solidification of CERCLA and RCRA Wastes: Physical Tests, Chemical Testing Procedures, Technlology Screening, and Field Activities. (1989). EPA/625/6-89/022, Office of Research and Development, USEPA, Washington, DC

- United Retek of Connecticut, LLC. unitedretekofct.com>

- USEPA. (1996) "Innovative Treatment Technologies, Annual Status Report".8th Edition, EPA/542/R-96/010, USEPA, Washington, DC.

- US EPA. (2012, December 13). Solidification. Retrieved March 13, 2013, from Contaminated Sites Clean-Up Information: http://www.clu-in.org/techfocus/default.focus/sec/Solidification/cat/Overview/

-

Wilk, C. (n.d.). Applying Solidification/Stabilization for Sustainable Redevelopment of Contaminated Property.

Lizzie Grobbel

Lizzie Grobbel  Zhijie Wang

Zhijie Wang

5 COMMENTS

Chris Ryan P.E.*

Mar, 21, 2013 There are several places where the authors are confusing the terms in situ and ex-situ stabilization and the advantages assocated with them. We would not define the movement of materials to a mixing pit and as in situ. Generally in situ is the use of some device, usually a mixing auger to mix the soils in place. As a result, there are no emissionsof volatiles or other materials, no dust, etc.Chris Ryan P.E.*

Mar, 21, 2013 This seems to be a pretty thorough review. The current state of practice is that these same technologies are being used with increasingly sophisticated reagents to chemically treat the soils as opposed to physically stabilizing them. The addition of activated carbon, specialized clays and granulated iron are examples of treatment additives. Lizzie Grobbel

Apr, 24, 2013 There are several places where the authors are confusing the terms in situ and ex-situ stabilization and the advantages assocated with them. We would not define the movement of materials to a mixing pit and as in situ. Generally in situ is the use of some device, usually a mixing auger to mix the soils in place. As a result, there are no emissionsof volatiles or other materials, no dust, etc.Chris,

Thank you very much for the valuable comments and for pointing out the ex-situ vs. in-situ error. We read through the references again and modified the field setup section to reflect this error.

Lizzie and Zhijie

Edit Comment

Sally Simpson*

Apr, 05, 2013 Lizzie and Zhijie,congratulations on an excellent review. I would agree with the comment about the in-situ vs. ex-situ. Make sure you address this.

Lizzie Grobbel

Apr, 24, 2013Sally,

Thank you very much for your comments and for pointing out the ex-situ vs. in-situ error. The field setup section has been corrected to reflect this error.

Lizzie and Zhijie

Edit Comment