Contents [show]

Introduction

Vertical barriers or “cutoff walls” are often used in geoenvironmental engineering to control the spread of contaminants. Cutoff walls in general can either be used to directly contain a contaminant by sealing it in from the outside environment or to manipulate the flow of groundwater to avoid contaminant transport through advection.Vertical barriers are often used along with surface caps or bottom barriers in order to create a more complete containment structure (CPEO website).

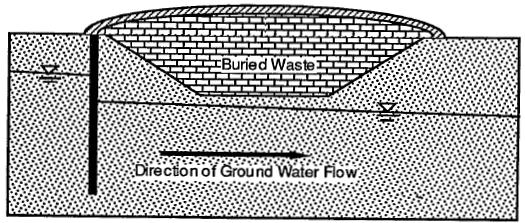

When groundwater flow is unknown the contaminant will most likely have to be completely surrounded by a wall that is keyed into an “impermeable layer”. Figure 1 shows a 2-dimensional view of a vertical cutoff wall completely surrounding a buried waste site with the walls keyed into a low permeability layer. Similarly, Figure 2 shows a plan view of a circumferential cutoff wall which contains pumping wells for remediation and monitoring wells for quality control. Theoretically, there should be no flow of either contaminants out or groundwater into the contained area (USEPA, 1995).

Figure 1: Circumferential Cutoff Wall Keyed into an “Impermeable” Barrier (USEPA, 1995)

Figure 2: Circumferential Cutoff Wall Showing Divergence of Groundwater Flow (USEPA, 1992)

Cutoff walls can be constructed in various configurations to manipulate the flow of groundwater. The vertical barrier can either be keyed-in into a low permeability layer, like the example shown in Figure 1, or they can be hanging, where the wall does not extend into a low permeability material. Hanging walls are typically used for floating contaminants or LNAPL’s, or to simply deflect the flow of groundwater. Vertical barriers can also be either upgradient or downgradient, which simply specifies whether the cutoff wall is respectively in front of or behind the contaminated area in relation to the flow of groundwater (USEPA, 1998; Van Deuren et al., 2002). A summary of cutoff wall configurations can be seen in Table 1. Figure 3 shows an example of an upgradient, hanging cutoff wall directing the flow of groundwater beneath a buried waste site.

Table 1: Cutoff-Wall Configuration Summary (USEPA, 1984)

Figure 3: Hanging, Upgradient Cutoff Wall (USEPA, 1995)

Cutoff walls are often used in combination with other remediation and containment techniques such as pumping wells and gravity drains. Figure 4 shows an example of a hanging, downgradient cutoff wall being used to stop the flow of a floating contaminant and a pumping well being utilized to remove the contaminant from the soil.

Figure 4: Cutoff wall, Pumping Well Combination for Remediation (USEPA, 1984)

Although cutoff walls are often referred to as impermeable barriers, they can never be truly impermeable (USEPA, 1995). Depending on the type of wall and the methods of installation, the hydraulic conductivity of cutoff walls can greatly vary, but can often exceed the minimum requirement for waste containment (10-7cm/s). There are many types of cutoff walls, but the main types discussed in this paper include slurry walls, grouted barrier walls, soil mixing walls, sheet pile walls and geo-membrane (GM) walls.

Slurry Walls

Theoretical Background/Applicability

Slurry walls are used to contain or divert contaminated groundwater from drinking water intake, divert uncontaminated groundwater flow from contaminated sites, and/or provide a barrier for the ground water treatment system (Van Deuren et al., 2002).

In general, slurry walls consist of a vertical trench excavated along the perimeter of a site, this trench is then filled with bentonite slurry for support and then backfilled with a mixture of low-permeability material, 1x10-6 cm/s or lower (USEPA, 1998). The three main types of slurry walls are soil-bentonite, cement-bentonite, and soil-cement-bentonite (see sections 2.1.1-3 for specifics). Depending on which type, the backfill may contain a mixture of bentonite, other clays, cement, fly ash, groundblasted furnace slag, among others (Pearlman, 1999).

Slurry walls are often used in cases that the waste mass of the contaminant is too large for treatment or where soluble and mobile constituents pose an imminent threat to a source of drinking water (Van Deuren et al., 2002).

Slurry walls have been used as a long-term solution for seepage control for over 50 years and have demonstrated its effectiveness to the point that they are considered baseline barriers. Therefore, the requirements, equipment, and practices for design and installation are well established (Pearlman, 1999; Van Deuren et al., 2002). In terms of pollution control, they have been used since the 1970s; the issue with this application is that specific contaminant types may degrade the slurry wall and therefore reduce the long-term effectiveness. Therefore, even though the design and installation criteria may be established, the process of choosing the proper wall materials for that specific contaminant is less developed (Van Deuren et al., 2002). Ressi and Cavalli (1985) adds that some suggest that this technology on its own should not be the final measure for remediation due to the fact that long-term performance of these walls when chemicals are present is not known.

The most effective vertical configuration of slurry walls for site remediation or pollution control is keyed-in, where the wall is keyed 2-3 feet into a low permeability layer, such as clay or bedrock, providing a foundation with minimum leakage potential (Van Deuren et al., 2002).

The following list contains factors, according to Van Deuren et al. (2002), that must be assessed prior of designing the slurry wall:

- The maximum allowable permeability;

- Anticipated hydraulic gradients;

- Required wall strength;

- The availability and grade of bentonite to be used;

- Boundaries of contamination;

- Compatibility of wastes and contaminants in contact with slurry wall material;

- Characteristics of backfill material;

- Site terrain and physical layout.

Slurry Walls Advantages (Pearlman, 1999; USEPA, 1998)

- Can reach hydraulic conductivities values less than 10-7 cm/s;

- This is the most common type of cutoff wall;

- Due to the fact that requirements and practices are well understood they are installed quickly;

- Depths of up to 200 ft can be reached;

- This is the only method that permits visual inspection of the key material and therefore assurance of the key-in depth during construction.

Slurry Walls Disadvantages (Sharma & Reddy, 2004)

- Depth above 50 ft require specialized equipement;

- Large excavation site, excavated soil storage, slurry mixing, material storage, etc.;

- It is hard to ensure integrity of the wall.

Field Setup/Process Involved

One of the most significant disadvantages of slurry trench construction is the extensive field setup required. The major construction process involved in the installation of a slurry trench include “preconstruction planning and mobilization, preparation of the site, slurry mixing and hydration, excavation of soil, backfill preparation, placement of backfill, cleanup of the site and demobilization” (USEPA, 1995). In order to accomplish all of this, a large site is typically required to accommodate the various mixing areas, storage of soils excavated, heavy machinery, etc. The components of construction of a typical slurry trench are depicted in Figure 5. Types of typical physical constrains affecting slurry wall construction are listed in Table 2.

Figure 5: Soil Bentonite Cutoff Wall Operation (Rumer and Ryan, 1995 as presented by Evans, 1995)

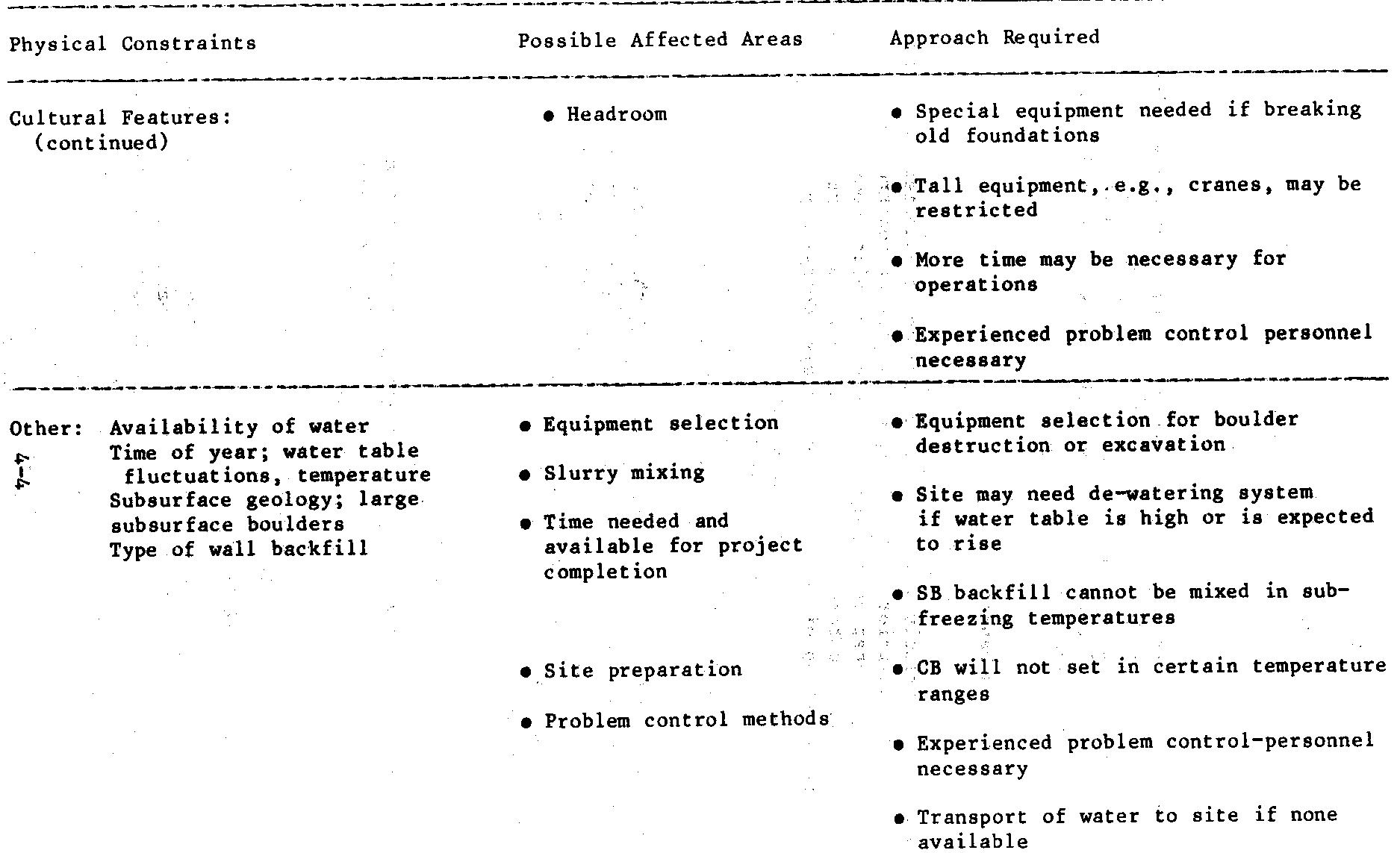

Table 2: Types of Physical Constraints and their Effects on Slurry Wall Construction (USEPA 1984)

Soil-Bentonite Slurry Walls

Theoretical Background/Applicability

Soil-bentonite (SB) slurry walls are the most widely used technique for containment in the U.S. (Katsumi et al., 2009; Pedretti et al., 2012; USEPA, 1998). As the name suggest, they are constructed by mixing a bentonite slurry with the excavated soil (USEPA, 1998; Van Deuren et al., 2002). USEPA (1998) reported that additional borrow material or dry bentonite might be added to the mixture in order to meet design requirements and that specialty additives have been added to the backfill in order to increase the sorption capacity.

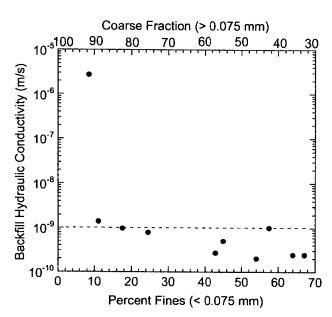

Bentonite provides a high sorptive capacity, thixotropic nature, high dispersibility, sufficient deformability, and low-permeability (Garving & Hayles, 1999; Katsumi et al., 2009). Figure 6, shows they hydraulic conductivity as a function of percent fines and coarse fraction of the backfill. However, Katsumi et al. (2009) suggest that in order to promote the application of soil-bentonite walls there are several issues to be solved such as “achieving the higher construction quality and understanding the chemical compatibility.”

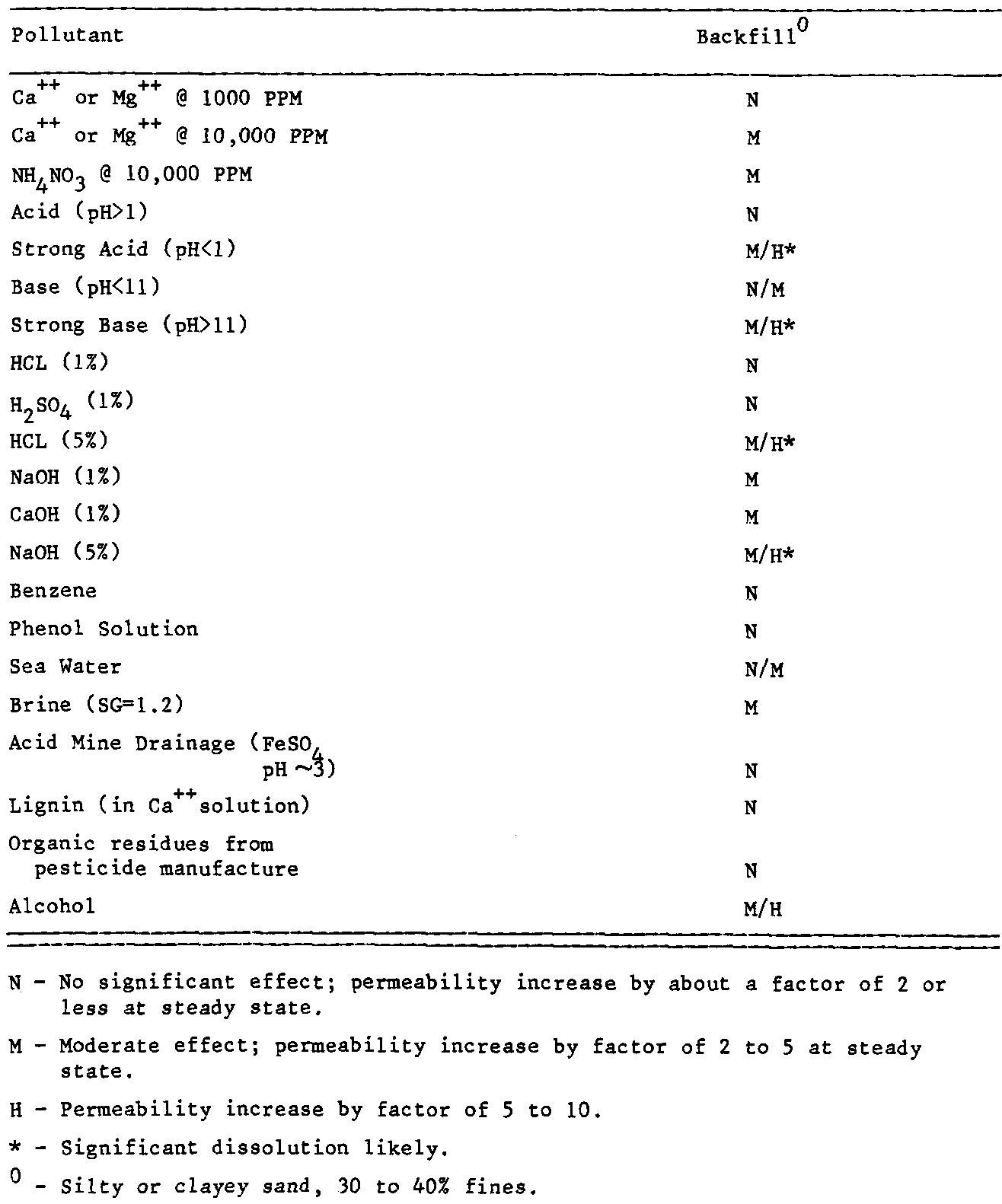

The hydraulic conductivity of bentonite-based material is affected by the chemical components of the permeant. It has been observed that bentonite does not swell and/or shrinks in the presence of inorganic solutions or some organic compounds. In the case of inorganic solution containing polyvalent cations the hydraulic conductivity can be increased, even at low concentrations (Katsumi et al., 2009). Table 3 shows a qualitative list of hydraulic permeability increase of certain contaminates through the SB wall. Therefore, its chemical compatibility should be assessed under the given conditions in the field.

Figure 6: Hydraulic Conductivity of Soil Bentonite Backfill as a Function of Percent Fines and Coarse Fraction of the Backfill (Benson, 2002)

Table 3: Soil-Bentonite Permeability Increases due to Leaching with Various Pollutants (USEPA 1984)

Advantages (Pearlman, 1999; Pedretti et al., 2012; USEPA, 1998)

- Among the slurry walls this is the most economical one;

- Most cases allow reuse of all or most of the material excavated during trenching;

- Construction techniques are well understood, practiced, and accepted;

- Typical hydraulic conductivity are around 10-7 cm/s, but can be as low as 5 x 10-9 cm/s.

Disadvantages (Pearlman, 1999)

- Installation requires excavation, therefore produces substantial quantities of spoils that must be disposed of, and requires a mixing area;

- Wet/dry cycles and freeze/thaw cycles can cause deterioration;

- This comfiguration is limited to vertical orientation;

- Assessment of performance is difficult;

- It is difficult to ensure proper emplacement;

- May degrade over time due to contaminants in the soil, for exaple:

- Silica and aluminum in the bentonite and/or soil may dissolve in the presence of strong organic and inorganic acids (pH 11) increasing the porosity of the barrier;

- Inorganic salts and some neutral polar and nonpolar organic compounds result in shrinkage of bentonite clay particles.

Cost (as presented in Pearlman, 1999)

In 1991, the cost ranged from $5 – $7/ft2, however these costs do not include cost needed for chemical analyses, feasibility, or compatibility test. Therefore, cost varies depending on site conditions, type of slurry/backfill, depth, among others.

Cement-Bentonite Slurry Walls

Theoretical Background/Applicability

Cement-bentonite (CB) slurry walls are a common form of vertical barriers in Europe, especially for seepage control in the UK (Garvin & Hayles, 1999; USEPA, 1998). They were initially used for water exclusion but now their use has extended to control migration of contaminants from industrial or landfill sites (Garvin & Hayles, 1999). Originally for the CB walls, cement was mixed with the bentonite slurry before refilling the trench. The first trials with CB slurry walls had problems since bentonite and cement start to react when mixed together, the slurry became nonhomogeneous and unstable, and due to flocculation and sedimentation, the solid and liquid phase separated. Therefore, now the bentonite and cement are mixed together as powder. These powders are available as commercial products (Koch, 2002).

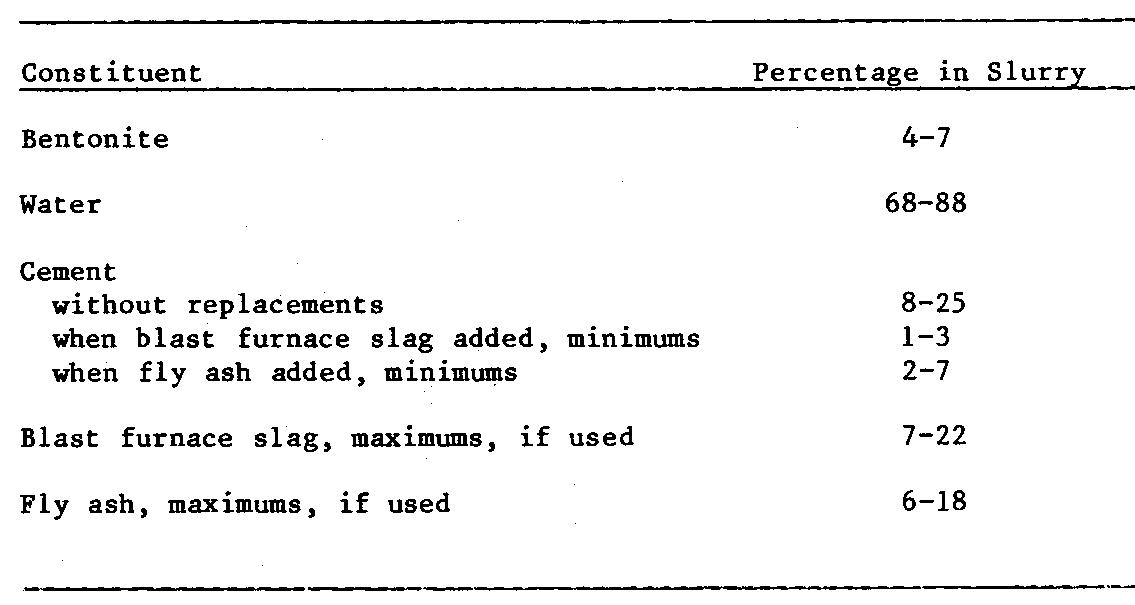

CB walls are used if greater structural strength is needed, if there is chemical incompatibility between bentonite and the site contaminants, if there is a lack of soil for backfill, if insufficient space is available for mixing of backfill, and/or for applications in steep slopes where shear strength of the cutoff walls is am issue (Pearlman, 1999; USEPA, 1998; Van Deuren et al., 2002). The most common cement used is Portland (Garvin & Hayles, 1999; Pearlman, 1999). Even though the CB imparts strength to the wall, it also increases the permeability of the backfill up to 10-5-10-6 cm/s, this becomes a problem since the typical required permeability is of 10-7 cm/s (Pearlman, 1999; USEPA, 1998). This behavior can be observed in Figure 7. However, additives such as ground-blast slag can be incorporated to the cement in order to reduce the permeability to 10-7-10-8 cm/s (Pearlman, 1999). Another concern with the CB walls is that contaminants can affect its long-term durability and performance (Garvin & Hayles, 1999). Pearlman (1999) suggests that adding fly ash can reduce the degradation of the concrete. Table 4 shows the typical composition of a cement-bentonite slurry. Table 5 and 6 compare some properties of soil-bentonite and cement-bentonite for the slurry and backfill, respectively.

Applications of CB walls include trench excavation adjacent to an existing structure or through soft or unstable soil (USEPA, 1998).

Figure 7: Hydraulic Conductivity of Soil Bentonite (Mixture A) and Cement Bentonite (Mixture B) (National Research Council, 2007)

Table 4: Typical Compositions of Cement-Bentonite Slurries (USEPA 1984)

Table 5: Specified Properties of Soil-Bentonite and Cement-Bentonite Slurries (USEPA 1984)

Table 6: Properties of Soil-Bentonite and Cement-Bentonite Backfills (USEPA 1984)

Advantages (Pearlman, 1999; USEPA, 1998)

- This configuration provides higher strength than SB walls;

- Self-hardening slurries do not require backfill, therefore CB walls can be constructed in limited access areas and at a lower cost;

- Can be used on steep slopes with unstable soil;

- Little or no slurry is displaced.

Disadvantages (Pearlman, 1999)

- It is difficult to ensure panel continuity;

- Some mixes can have undesirable high permeability (e.g., Portland cement can adversely affect the swelling of bentonite clay);

- Often difficult to achieve sufficiently low permeability;

- Cracking due to shrinkage, thermal stress, and wet/dry cycling can occur.

Cost (as presented by Pearlman, 1999)

Cost ranges from $10 – $20/vertical ft2 for a 2-ft wide barrier of less than 100 ft.

Soil-Cement-Bentonite Slurry Walls

Soil-cement-bentonite (SCB) slurry walls are combination of the SB and CB walls. An advantage of SCB wall is that they provide similar strength to CB wall while providing similar hydraulic conductivity to SB walls (Pearlman 1999).

Grouted Barrier Walls

Theoretical Background/Applicability

In general, grouting technology consists of injecting a fluid material at a certain pressure into soil or rock in order to decrease the permeability and/or strengthen the formation (USEPA, 1984). Grouted barriers have higher permeability than other techniques such as slurry and geomembrane walls, and therefore have been used less frequently at hazardous waste sites. They are capable of extending the key of other types of barriers, like slurry walls, through the bedrock in situations were standard excavation equipment is not adequate or is too costly (USEPA, 1984; USEPA, 1998).

Grout walls are typically formed by overlapping grout columns which form a single row. Additional rows can be added to ensure the effectiveness of the wall (Pearlman 1999).

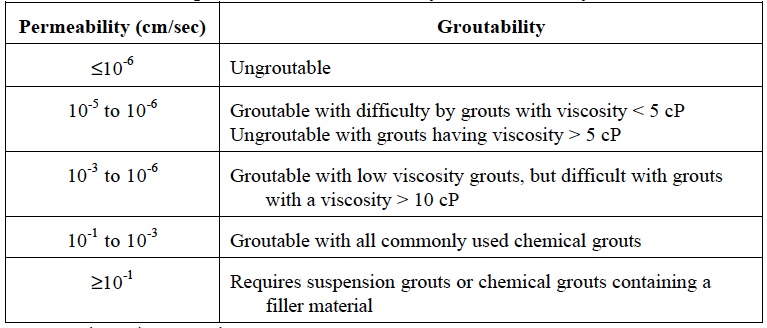

The ability of the soil to receive the grout is known as groutability. This parameter depends on the permeability of the soil and the viscosity of the grout. Higher viscosity grouts are more suitable for high permeability soils (Pearlman, 1999). Table 7 shows the relationship between the permeability of the soil and its groutabiltiy.

Table 7: Relationship Between Soil Permeability and Grouting (Karol 1990 in Voss et al., 1994 as presented by Pearlman 1999)

Grouted Barrier Walls Advantages (Sharma & Reddy, 2004)

- Depths greater than 200 ft can be achieved;

- Ideal for situations involving fractured rock;

- Little waste material is generated.

Grouted Barrier Walls Disadvantages (Sharma & Reddy, 2004)

- This configuration involves more cost;

- Relatively high hydraulic conductivity values are obtained.

Jet Grouting

Theoretical Background/Applicability

According to Pearlman (1999) the methods for jet grouting can include a single-rod system (injection grout alone), a double-rod system (injecting grout and air) or a triple-rod system (injecting grout, air, and water). Usually the grout consists of Portland cement or cement-bentonite and may include other clays and silicates (CPEO website; Pearlman, 1999). Due to the fact that these materials may not be chemically compatible with the contaminants they may crack and/or may not be durable. Therefore, polymer grouts have been used. Polymer grouts are resistant to radiation, as well as acidic and alkaline environments (CPEO website).

In general this technique injects the grout mixture at very high pressures and velocities (5,000-6,000 lbs/in2 and 800-1,000 ft/s, respectively) directly into the pore spaces of the soil or rock. The grout being injected cuts, replaces, and mixes the in situ soil, destroying the soil structure and forming a homogeneous mass. As the rod is being removed and the grout is being injected, a column is formed (Pearlman, 1999). Each time the rod is inserted in such a way that each column intersects the next, therefore forming a continuous wall or curtain (CPEO website).

Pearlman (1999) suggests that this method can be applied to soil ranging from gravel to clay, however the soil properties can alter the diameter of the grout column and the efficiency as jet grouting in clay is less efficient than in sand. According the CPEO website, high-pressure jetting appears to be a cost effective means to place physical barriers in unstable soils, near foundations, and around underground obstructions.

Advantages (Mutch et al., 1997; Dwyer, 1998 as presented by Pearlman, 1999)

- Versatile – jet grouting can stabilize a wide variety of soil types ranging from gravel to heavy clays

- Starting from a small borehole, large diameter columns or panels can be created

- Can install wall (inject) in confined places that might otherwise limit installation – for instance, cut-off walls can be constructed beneath buildings without disrupting the structure

- Installed at depths up to 150 – 200 ft

- Can drill at any angle forming both vertical and horizontal water control barriers

- Jet grout unit is mobile, permitting drilling with rotation and percussion

- Down-the-hole (DTH) percussion hammer coupled with the drill string results in more reliable drilling alignments (straight and parallel), faster drilling rates, and a quieter operation

- Innovative equipment allows injection of multiple fluids or gasesCan be used in coordination with treatment

- DTH percussion hammer

- Multi-nozzle grout injection unit increases the efficiency of injection

Disadvantages (Rumer et al., 1995 as presented by Pearlman, 1999)

- Difficult to ensure panel continuity (verticality is critical to ensure that gaps will not occur between panels)

- Boreholes can become misaligned

- Obstruction of jet nozzle can be a problem

- Different soil types and densities affect ability to grout

- Gaps between panels or thin spots may lead to cracking

- Separation or tears may occur as barriers harden

- Potentially large amount of spoils to clean up

- Injection pressure and volume must be closely monitored

Field Setup/Process Involved

As previously mentioned there are three main types of jet grouting, single, double and triple rod. Single rod jet grouting injects only grout into the soil and is capable of creating columns that can be up to 1.2 m in diameter in granular soils and up to 0.8 m in diameter in cohesive soils. In double rod jet grouting air is injected along with the grout in order to clear the jet stream of soil and groundwater. Double rod jet grouting columns can potentially have twice the diameter as single rod columns but tend to be more permeable due to the added air content. Triple rod jet grouting injects water and air in a separate jet which cuts and lifts the in-situ soil. The grout is injected through another jet so that a column comprised of almost pure grout is formed as the drill rod is lifted. These columns can have diameters as large is 3 m in granular soils and 1.5 m in cohesive soils. A triple rod jet grouting setup injecting grout, water and air into the soil is depicted in Figure 8 (USEPA, 1998).

Figure 8: Jet Grouting Wall Construction Setup (Evans, 1995)

Cost (as presented by Pearlman, 1999)

Cost ranges from $15 – $30/vertical ft2.

Permiation Grouting

Theoretical Background/Applicability

Unlike jet grouting, permiation grouting injects a low-viscosity grout into the soil at low pressure. The grout fills the soil voids, achieving low permeability without significantly changing the structure or volume of the soil (Pearlman, 1999).

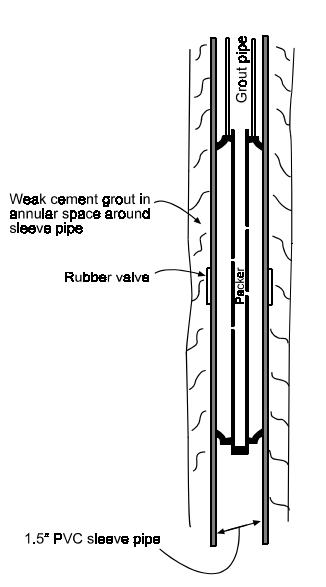

In general, a hole is drilled into the ground and a fluid is injected under pressure into the soil or rock, permeating the voids (Ryan, 1987). The two main methods of permiation grouting are point injection and sleeve pipe injection. For point injection, the casing is first driven to full depth then as the casing is withdrawn the grout is injected. For the latter, as the name suggests, a sleeve pipe is inserted in the grout hole and grout is then injected through the holes in the pipe. An advantage of the sleeve pipe injection method is that grout can be re-injected if there is a problem (Pearlman, 1999).

Permiation grouting is a useful technique to achieve low permeability barriers in semi- arid unconsolidated alluvial soils and where a barrier is needed in a rock formation (Pearlman, 1999; Ryan 1987).

Advantages (as presented by Pearlman, 1999)

- In situ technique means lower costs because there is no excavated soil

- Directionally drilled boreholes allow access without disturbing the waste

- Can be used to emplace vertical or horizontal barriers for complete containment

- Appliable for short-term or long-term applications

- Barriers may enhance the effectiveness of in situ remediation while containing the volume of waste

- Applicable to rock

Disadvantages (as presented by Pearlman, 1999)

- Limited to formations with moderate to high permeabilities

- Hard to ensure continuity

- Difficult to direct the flow of grout in heterogeneous soils because the grout tends to follow the path of least resistance

- Hard to predict grout penetration radius

Field Setup/Process Involved

The two main methods used for permeation grouting are point injection and the tube-a-manchette method. The point injection method simply involves advancing the grout casing to the required depth and then, as the casing is withdrawn, grout is extruded through the end of the casing. The tube-a-manchette method involves grouting a sleeve pipe into a borehole with a weak grout. The pipe contains small holes at 1-ft intervals which are all covered by rubber sleeves (manchettes) which acts as a one-way valve. A double packer is placed in the pipe so that it straddles the manchettes so that pressurized grout can be injected in to the soil. Because the tubes can be left in the ground, this method allows for further addition of grout of other additives at a later date. A depiction of a tube-a-manchette apparatus is shown in Figure 9 (USEPA, 1998).

Figure 9: Tube-A-Manchette Permeation Grout Apparatus (From USEPA 1998)

Soil Mixing Walls

Theoretical Background/Applicability

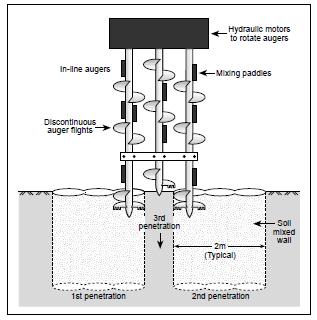

Deep soil mixing walls consist of “overlapping columns created by a series of large diameter counter rotating augers mixing” (USEPA, 1998) in situ soils with low permeability slurry creating a column of treated soil (Pearlman, 1999; Ryan, 1987; USEPA, 1998). Such slurry is injected through the augers producing a hard mass, which then acts as a barrier (Pearlman, 1999). The types of slurry will vary depending on the site conditions similar to slurry walls. Common materials for the slurry include bentonite, cement, lime, fly ash, among others (Pearlman, 1999). A continuous wall may be constructed if individual columns are overlapped.

Soil Mixing Walls Advantages (as presented by Pearlman, 1999; Ryan 1987)

- These walls are capable of having hydraulic conductivitie values lower than 10-7 cm/s

- Little waste material is generated during wall construction

- Construction can take place in reletively confined areas

- Any tiype of waste can be contained as long as “a chemical or physical reagent is applicable”

- Does not require an open excavation

- There is a low cost involved when compared to jet grouting

Soil Mixing Walls Disadvantages (as presented by Pearlman, 1999)

- The bottome of the wall can not be inspected to ensure that it is properly keyed in

- Hard ground or large boulders in the subsurface limit drilling ability

- The continuity of the wall is difficult to ensure do to the use of many interconected holes or panels

- The amount of bentonite that is added to the soil is limited

- Maximum drilling depth limited to 40-100 ft

Field Setup/Process Involved

Soil mixing typically requires the use of a rig fitted with either one, or a panel of multiple, mixing augers. Figure 10 shows a panel of three counter rotating augers. While the soil is being mixed materials such as cement and bentonite are injected to create a panel of low hydraulic conductivity. Subsequent panels are then overlapped to create a cutoff wall. (Evans, 1995)

Figure 10: Deep Soil Mixing Wall Construction (Evans, 1995)

Cost (as presented by Pearlman, 1999)

The cost varies depending on the soil characteristics and the grout material used. For example, soil-cement is more expensive than soil-bentonite (Rumer er al., 1996). The following are some cost estimates:

- $10 – $20/vertical ft2

- $40 – $50/yd3 (cost does not include reagent)

- Cost ranges from $6 – $15/ft2 for deep mixing, and $15 – $30/ft2 for DSM structure

Sheet Pile Walls

Theoretical Background/Applicability

In general, sheet pile walls may consist of steel, precast concrete, aluminum, wood, among others (Pearlman, 1999; USEPA, 1984). For containment of contaminants steel is the most applicable material. The sheets are assembled before installation and can be either driven or vibrated into the ground, in either case, the sheet is lowered a few feet at a time (Pearlman, 1999). A major advantage of using sheet pile walls is that it provides strength (McMahon, 1995). A continuous wall is constructed by joining the sheets together. These joints are considered to be the major weakness of sheet pile walls (McMahon, 1995; Pearlman, 1999). Another concern is potential corrosion of the steel due to long-term exposure to some chemicals (McMahon, 1995).

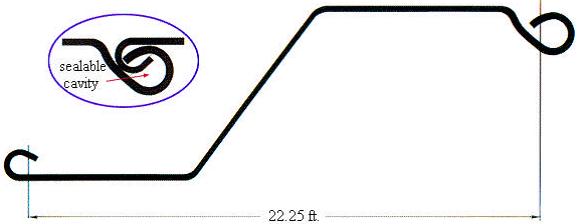

Traditional sheet pile walls are widely used for civil engineering projects but their use in geoenvironmental applications is limited due to leakage between the panel interlocks (McMahon, 1995). Several innovative designs have been developed to address the problem of leakage between the interlocks including the Waterloo Barrier which is shown in Figure 11. The Waterloo barrier is able to achieve hydraulic conductivities of less than 10-8 cm/s (Pearlman, 1999 previously from Mutch et al., 1997) by sealing the joints between each sheet.

Figure 11: Waterloo Barrier Schematic (Mutch et al., 1997 as presented by Pearlman, 1999)

Sheet Pile Walls Advantages (Sharma and Reddy, 2004)

- Damaged wall section can be easily removed and replaced

- Depths of 50 to 100 ft can be reached depending on conditions and equipment

- Installation is very rapid when compared to other types of cutoff wall construction

- These walls have high strengths which is ideal for durability or if any type of reinforcement is required

- Little to no waste materials are generated during constuction

- Transport through means of diffusion is greatly reduced

Sheet Pile Walls Disadvantages (Sharma and Reddy, 2004)

- Steel walls are generally susceptible to salts and acids

- Interlock leakage can be quite significant for standard sheet pile joints

- Steel is very expensive when compared to other construction materials

- Piles can be hard to drive if boulders are present and also hard to key into low permeable layers

- Standard sheet pile walls usually do not have hydraulic conductivity values greater than 10-7 cm/s

Cost (as presented by Pearlman 1999)

The cost of a sheet pile barrier ranges from $15 – $40/ft2 depending on the depth, equipment used, type of joint, and type of sealant.

Field Setup/Process Involve

Sheet pile walls are fairly easy to install and do not require any previous excavation. Interlocking sheet piles, typically made of steel, are simply inserted into the ground one by one. The piles are either driven or more commonly vibrated to the necessary depth. For greater depths, additional piles are simply welded to the piles already inserted into the ground. If sealable joints are used, the joint cavities are flushed of all soil and debris and then a sealant is injected into the cavity (Pearlman, 1999).

Geomembrane walls

Theoretical background/Applicability

Geomembranes have been used in vertical wall applications since the 1980s. Due to the concerns of the integrity of slurry walls, geomembranes have been used as a complementary strategy to the standard slurry walls providing a more complete containment structure. However, geomembranes have also been used by themselves as a separate technology (Koerner & Guglielmetti, 1995; Thomas & Koerner, 1996).

High density polyethylene (HDPE) is the most common material used due to the fact it is highly resistant to water vapor transport and to a variety of other chemical. Moreover, it has been used extensively in other geotechnical applications and therefore is readily available (Koerner & Guglielmetti, 1995; Thomas & Koerner, 1996). However, HDPE does not provide enough stiffness in order to directly drive the material into the soil. Therefore, in cases that direct driving is required polyvinyl chloride (PVC) may be used (Koerner & Guglielmetti, 1995).

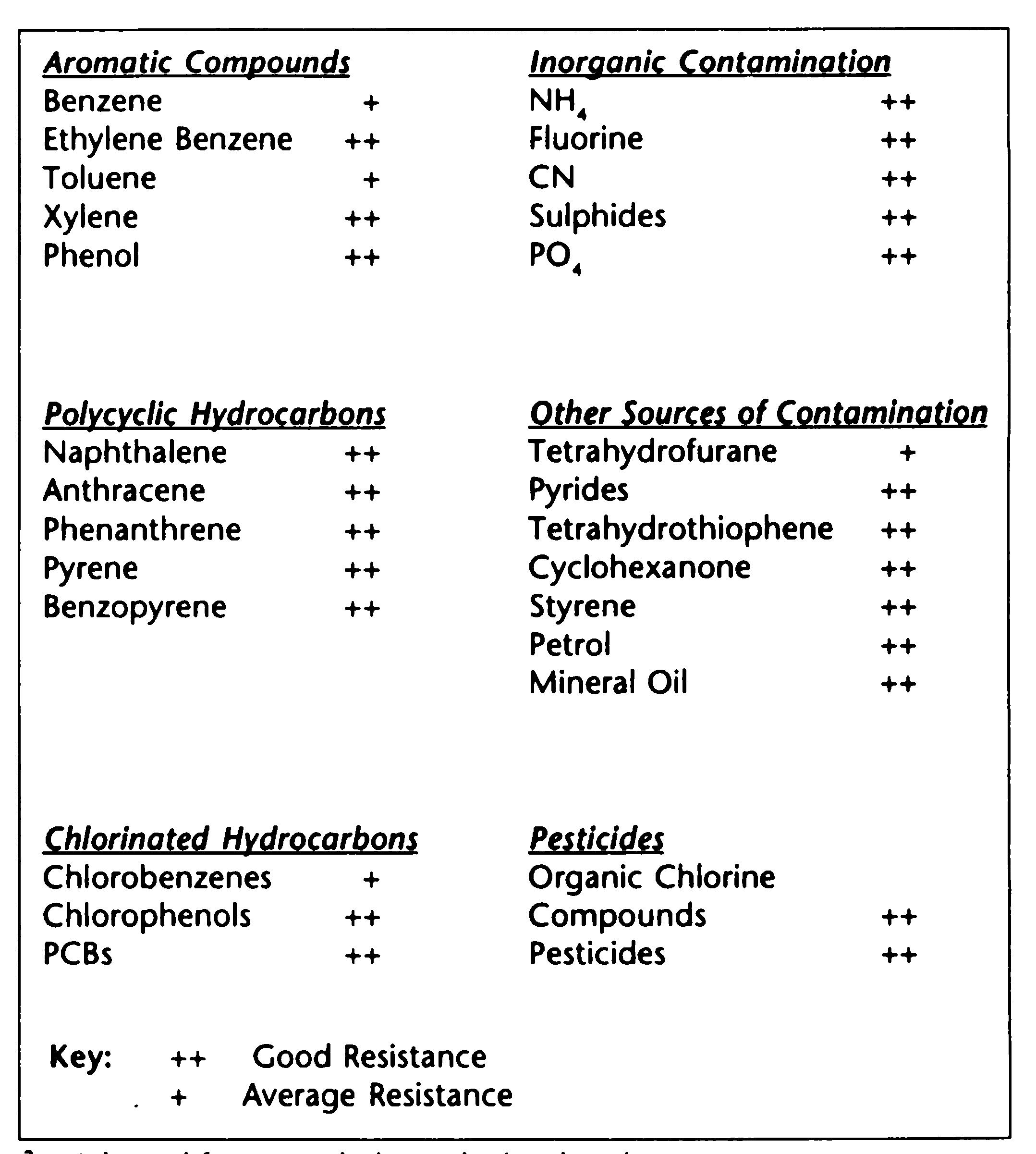

Figure 12 shows a qualitative resistivity of HDPE geomembranes to several chemicals. Concentrated hydrocarbons, especially chlorinated and aromatics, can produce a loss in tensile yield strength of up to 30%, though it has been seen that this behavior is reversible when the compounds are allowed to vent off (Thomas & Koerner, 1996). Moreover, Table 8 shows the vapor transmission rates of several organic solvents through HDPE geomembranes. Some factors that affect the rate of permeation through the membrane include chemical concentration, temperature, and sheet thickness.

Figure 12: Relative Chemical Resistivity of an HDPE Geomembrane (as presented by USEPA 1992

Table 8: Vapor Transmission Rates of Organic Solvents Through HDPE Membranes (Park et al., 1995 as presented by Thomas & Koerner, 1996)

Geomembrane Walls Advantages (Koerner & Guglielmetti, 1995; Ressi & Cavalli, 1985; Thomas & Koerner, 1996)

- Can ensure continuity of extremely low hydraulic conductivity values (as low as 10-12 cm/s), when good connection of interlocks exist

- Added chemical resistance, including organic solvents

Geomembrane Walls Disadvantages (Koerner & Guglielmetti, 1995; Thomas & Koerner, 1996)

- Hard to assure quality installation

- Not stiff enough to be directly driven into the soil like steel sheets

Additional advantages and disadvantages for individual geomembrane wall construction methods are listed below in Table 9.

Table 9: General Assessment of Geomembranes as Vertical Barriers (Rumer et al., 1996 as presented Pearlman 1999)

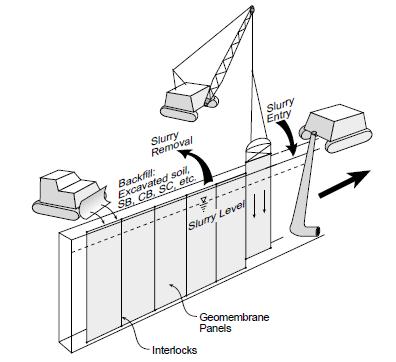

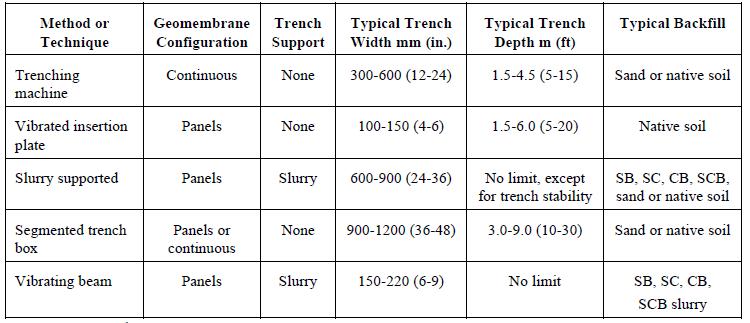

Field Setup/Process Involved

Geomembranes can either be used alone to form a vertical barrier or in conjunction with other technologies such as slurry trenches. Geomembrane walls are usually constructed from interlocking panels but can also be rolled out in a trench to form a continuous wall. A geomembrane/slurry wall combination schematic can be seen in Figure 13. The typical methods used for the construction of geomembrane cutoff walls are listed in Table 10 and include the use of a trenching machine, vibrated insertion plates, slurry support, a segmented trench box and a vibrating beam (Evans, 1995 and Pearlman, 1999).

Figure 13: Geomembrane/Slurry wall combination (Evans, 1995)

Table 10: Installation Methods for Geomembrane Vertical Barriers (Rumer et al., 1996 as presented Pearlman 1999)

Other Considerations

There are many other methods for creating cutoff walls which are generally used less frequently than the ones previously listed. A few of them are listed below in Table 11 with some brief information.

Table 11: Additional Methods for Constructing Vertical Cutoff Barriers

Pearlman (1999) presents some key factors that should be taken into consideration when choosing, designing, and constructing the barrier system:

- Establish the barrier geometry (alignment, depth, and thickness)

- Perform compatibility testing in order to select the most effective barrier material and if necessary appropriate mixture conditions

- Determine the most effective and feasible construction method

- Construction quality assurance/quality control and monitoring should be taken into account since they are a crucial component of subsurface barrier design.

When constructing a cutoff wall there are several factors to consider including time, available space, cost, target permeability, etc. Table 12 compares some of the important factors for several of the most common types of cutoff walls.

Table 12: Comparison of Passive Vertical Containment Barriers (Shackelford & Jefferis, 2000)

Case Histories

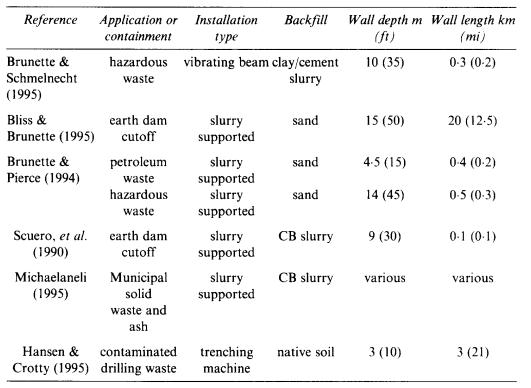

Geomembrane Wall

Table 14 briefly summarizes several case studies involving the use of geomembranes in vertical barriers. Among the cases listed is a cutoff wall encompassing a Great Lakes chemical plant to prevent the spread of contaminated groundwater, previously described by Burnette and Schmednecht (1994). The wall was constructed through layers of sand, gravel and cobbles by means of the vibrating beam installation method. The 4 ft wide, 80 mil thick, HDPE panels were inserted into a 5 inch wide trench supported by a clay/cement slurry which was up to 35 ft in depth. The average rate of production for this project exceeded 1100 square feet per day.

Another case history summarized in Table 13 consisted of a 21-mile geomembrane wall constructed to contain drilling fluids in Alaska’s North Slope oil fields. The wall primarily consisted of a double lined system consisting of both HDPE, reinforced polyurethane and reinforced PVC geomembranes. The geomembrane was rolled out in a 12 inch wide trench with the roll ends seamed by thermal fusion. The wall, typically 10 ft in depth, was keyed in to the permafrost. The wall was constructed in temperatures reaching as low as -44°C and production rates were typically 500 ft for a 10 hr sheet.

Table 13: Summary of Case Studies Utilizing Geomembranes as Cutoff Walls (after Koerner & Guglielmetti, 1995 as presented by Thomas & Koerner, 1996)

Sheet Pile Wall/Drain Combination

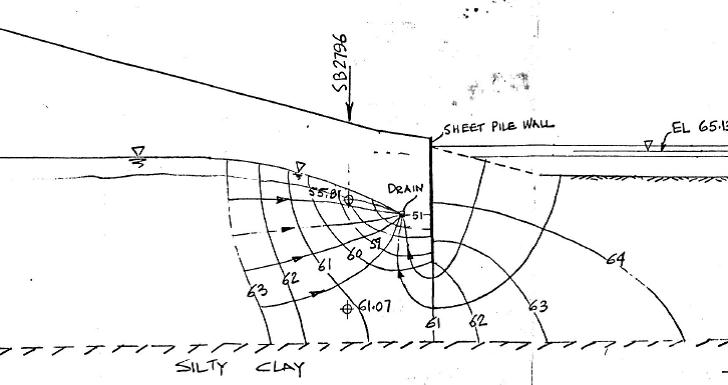

In the early 80’s McDowell & Associates designed a containment system which incorporated the combination of a gravity drain and a downgradient sheet pile wall to stop the spread of contaminants into an adjacent river. For most of the length of the system, the sheet pile wall was keyed into a low permeability silty clay but deep sand deposits, believed to be from a past river channel, were occasionally encountered where the sheet pile wall was left hanging. A study which involved the measurement over time of both the river level and the readings from several piezometers was conducted and it was concluded that there was some potential for seepage into the river. To overcome this potential seepage, pumping wells were installed in specified locations to further lower the water table of the contaminated site. In this project the cutoff wall was primarily used to manipulate the groundwater flow rather than for direct containment. The flownet shown in Figure 14 was constructed to show an area were there was no potential for contaminant seepage to the river in a zone where the sheet pile wall was not keyed into the silty clay. (McDowell, 1983)

Figure 14: Flownet for Containment System Designed by McDowell & Associates (McDowell, 1983)

Slury Wall Common Mistakes

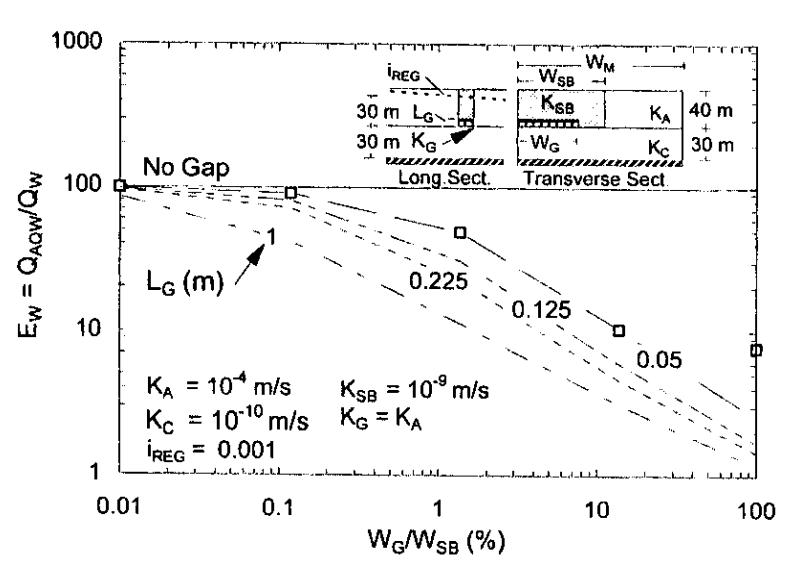

The following brief case histories taken from Benson (2002) are examples of some common ways a cutoff wall can be insufficient. The first case consisted of a soil bentonite wall with a hydraulic conductivity of 5x10-9 m/s utilized to isolate a lagoon from the surrounding groundwater in the western United States. The wall was to be keyed into the underlying bedrock. The bedrock consisted of claystone which was overlain by a relatively thin sandstone layer. Excessive leakage quickly became apparent and pump tests revealed that the 1.9 km wall was leaking approximately 1000 m3/day, which was 100 times the expected value. Further investigation revealed that 48% of the wall was keyed into the relatively pervious sandstone instead of the relatively impervious claystone. The reasons for the lack of a proper key came down to lack of proper site investigation prior to construction and the fact that the engineer for the job was only on site for the first day. A previous study by Techavises (1998) described the effectiveness of a cutoff wall for varying gaps between the wall and the “impervious layer”,the relationship can be seen in Figure 15.

Figure 15: Wall Effectiveness as a Function of Gap Size between the Wall and the “impervious layer” (From Tachavises, 1998 as presented by Benson, 2002)

The next case consisted of a soil bentonite cut-off wall to isolate a plume emanating from an uncovered landfill. The stratigraphy consisted of approximately 16 m of granular material underlain by 10 m of thick clay till. The wall was constructed with conventional slurry wall methods and the backfill was mixed using the soil excavated from the trench. The backfill was to have a hydraulic conductivity greater than 1x10-9 m/s, fines content greater than 30% sand content less than 15%. During construction sand contents reached as high as 41% despite specifications and warnings from the engineer. When the engineer would not certify the wall, a drilling program was conducted to verify the integrity of the wall. The program discovered the presence of windows with permeability’s as low as 2x10-6 throughout the wall where sand content exceeded 20%. Because the engineer would not sign off on the wall, the contractor was forced to fix the wall through the process of deep soil mixing. Another study by Techavises (1998) analyzed the effectiveness of a slurry cutoff wall with high permeability windows, the results can be seen in Figure 16.

Figure 16: Effect of High Permeability Windows on Wall Performance (From Tachavises, 1998 as presented by Benson, 2002)

The third case consisted of a project where segments of a soil bentonite slurry wall were being replaced by a cement bentonite wall that had to have a hydraulic conductivity less than 1x10-8 and compressive strengths exceeding 175 kPa at a hazardous containment site. The reason for the replacement was that the liquid contaminants were apparently too aggressive for the soil bentonite wall. Sampling of the wall was conducted by making cylinder molds to be tested after seven days and at a later date. The first set of samples did not meet the strength requirements so core samples were taken to determine if further curing strengthened the wall. Testing showed that neither the hydraulic conductivity nor the strength was adequate. Further core samples were taken with even higher hydraulic conductivities and lower strengths and a test pit was eventually dug. It was then suggested that disturbance to the samples may have contributed to the unacceptable test values. Further testing on the cylinder samples which had been held to test at a later date affirmed that the previous samples were most likely disturbed, the test results were all less than the specified hydraulic conductivity and greater than the specified strength. In this case a large amount of time effort and money was spent due to inadequate sampling methods.

Recommended Readings

- Pearlman, L. (1999). Subsurface Containment and Monitoring Systems: Barriers and Beyond. U.S. EPA, National Network of Environmental Management Studies, Washington, DC.

- Rumer, Ralph R. and Mitchell, J. K. (1995) Assessment of Barrier Containment Technologies - A Comprehensive Treatment for Environmental Applications, U.S. Department of Energy, U.S. Environmental Protection Agency, Dupont Company, Baltimore.

- Sharma, H. D., and Reddy, K. R. (2004). Geoenvironmental Engineering. Wiley & Sons, Inc., Hoboken, New Jersey.

- U.S. EPA. (1998). "Evaluation of Subsurface Engineered Barriers at Waste Sites." U.S. EPA, Office of Solid Waste and Emergency Response.

- U.S. EPA. (1984). "Slurry Trench Construction for Pollution Migration Control." U.S. EPA, Ofice of Emergency and Remedial Response and Office of Research and Development Municipal Environmental Research Laboratory.

References

- Benson, C. H. (2002). "Containment systems: Lessons learned from North American failures." Edited by L.G. de Mello and M. Almeida. Fourth International Congress on Environmental Geotechnics.: Swets & Zeitlinger, Lisse, Rio de Janeiro, Brazil, 1095-1112.

- CPEO. "Grout Curtains." Center fro Public Environmental Oversight, http://www.cpeo.org/techtree/ttdescript/grocur.htm> (Feb. 2013).

- Evans, J. C. (1995). "Soil- and cement- based vertical barriers with focus on materials." In Assessment of Barrier Containment Technologies - A Comprehensive Treatment for Environmental Applications, U.S. Department of Energy, U.S. Environmental Protection Agency, Dupont Company by Ralph R. Rumer and James Kenneth Mitchell, Baltimore, 5-43.

- Garvin, S. L., and Hayles, C. S. (1999). "The chemical compatibility of cement-bentonite cut-off wall material." Construction and Building Materials 13, 329-341.

- Katsumi, T., Inui, T., and Kamon, M. (2009). "In-Situ Containment for Waste Landfill and Containment Sites." Int. Symp. on Geoenvironmental Eng. Hangzhou, 248-258.

- Koch, D. (2002). "Bentonites as a basic material for technical base liners and site encapsulation cut-off walls." Applied Clay Science 21, 1-11.

- Koerner, R. M., and Guglielmetti, J. L. (1995). "Vertical Barriers: Geomembranes." In Assessment of Barrier Containment Technologies - A Comprehensive Treatment for Environmental Applications, U.S. Department of Energy, U.S. Environmental Protection Agency, Dupont Company by Ralph R. Rumer and James Kenneth Mitchell, Baltimore, 95-118.

- McDowell and Associates. Unpublished internal report, 1983.

- McMahon, D. R. (1995). "Vertical Barriers: Sheet Piles." In Assessment of Barrier Containment Technologies - A Comprehensive Treatment for Environmental Applications, U.S. Department of Energy, U.S. Environmental Protection Agency, Dupont Company by Ralph R. Rumer and James Kenneth Mitchell, Baltimore, 77-93.

- National Research Council Comitee to Assess the Performance of Engineered Barriers. (2007). Assessment of the Performance of Engeneered Waste Containment Barriers, The National Academic Press, Washington, D.C.

- Pearlman, L. (1999). Subsurface Containment and Monitoring Systems: Barriers and Beyond. U.S. EPA, National Network of Environmental Management Studies, Washington, DC.

- Pedretti, D., Masetti, M., Marangoni, T., and Beretta, G. P. (2012). "Slurry wall containment performance: monitoring and modeling of unsaturated and saturated flow." Environ Monit Assess, 184, 607-624.

- Ressi, A., and Cavalli, N. (1985). "Bentonite Slurry Trenches." Engineering Geology, 21, 333-339.

- Ryan, C. R. (1987). "Vertical Barriers in Soil for Pollution containment." Geotechnical Special Publication 13, 182-204.

- Shackelford, C. D., and Jefferis, S. A. (2000). "Geonenvironmental ngineering for in situ remediation." International Conference on Geotechnical and Geoenvironmental Engineering, Technomic Publ. Co., Inc., Melbourne, Australia, 121-185.

- Sharma, H. D., and Reddy, K. R. (2004). Geoenvironmental Engineering. Wiley & Sons, Inc., Hoboken, New Jersey.

- Thomas, R. W., and Koerner, R. M. (1996). "Advances in HDPE Barrier Walls." Geotextiles and Geomembranes 14, 393-408.

- U.S. EPA. (1998). "Evaluation of Subsurface Engineered Barriers at Waste Sites." U.S. EPA, Office of Solid Waste and Emergency Response.

- U.S. EPA. (1995). "Quality Assurance and Quality Control for Waste Containment Facilities." National Risk Management Research Laboratory, Cincinati, OH.

- U.S. EPA. (1984). "Slurry Trench Construction for Pollution Migration Control." U.S. EPA, Ofice of Emergency and Remedial Response and Office of Research and Development Municipal Environmental Research Laboratory.

- U.S. EPA. (1992). "Slurry Walls." U.S. EPA, Office of Emergency and Remedial Response, Office of Research and Developement.

- Van Deuren, J., Lloyd, T., Chhetry, S., Lious, R. and Peck, J. (2002). Remediation Technologies Screening Matrix and Reference Guide, 4th Edition. U.S. Army, Environmental Center, Platinum International, Inc.

Margarita Otero

Margarita Otero  David Quintal

David Quintal

6 COMMENTS

Ata*

Mar, 26, 2013 Hi,You have done an excellent job. I only have a comment?

Is it a disadvantage to have a lower cost than jet grouting?

Good luck,

Ata

David Quintal

Apr, 22, 2013 Ata,Having a lower cost than jet grouting was supposed to be in the advantages section. Thank you for catching the mistake, it has been corrected.

Thanks,

David and Margarita

Edit Comment

Schillig*

Apr, 03, 2013 This is a great report. I found it to be a very helpful compilation and comparison of various types of vertical walls that can be utilized for a variety of projects. The concise Advantages/Disadvantages comparison was particularly informative. Overall the report is well written and a useful reference for both students and professionals. I do have a few constructive thoughts for the authors. 1) It may be worthwhile to add an extra step in the analysis of literature data to better dovetail findings from multiple sources. For instance, advantages from references Pearlman 1999 and USEPA 1998 indicate depths up to 200 ft are possible for installation of a slurry wall. Under the disadvantages heading of the same section, information from Sharma & Reddy 2004 indicates that it is difficult to exceed 50 ft of installation depth. 2) The authors may also wish to consider inflation to adjust their reported costs from the cited cost as the cited reference is a bit dated. 3) The authors may wish to revise the sentence in 2.1 where a K that is greater than 10^-7 cm/s is an advantage. It seems counterintuitive to me to want a higher K in a slurry wall.Nice job!

Margarita Otero

Apr, 22, 2013 Schilling,1) We see how some of the information listed from different authors can be confusing and somewhat contradicting. We have gone through and altered the parts where we thought this was the case.

2) You bring up a good point but the reason for not adjusting the published values was simply that we did not want to apply the standard inflation rate to all the various walls when each one will have its own rate depending on materials used, etc. We may however consider adding a footnote stating that inflation values should be taken into consideration.

3) The sentence has been corrected to say less than 10^-7, thank you for bringing this typo to our attention

Thanks,

David and Margarita

Edit Comment

Sally Simpson*

Apr, 04, 2013 David and Margarita,good job overall. Very informative. Any feeling about which cutoff walls are the most commonly used? For example, are geomembrane cutoff walls common? I think they are not as common as the other cutoff walls.

David Quintal

Apr, 23, 2013 Ms. Simpson,As we mention in section 2.1, slurry walls are by far the most common type of cutoff wall used for geoenvironmental applications. As far as the other types of walls, we did not come across any specific distributions. As you suspected, geomembrane walls are typically less common than some of the other types of walls, this is partially due to the relatively short time period that they have been around.

Thanks,

David and Margarita

Edit Comment